Workholding

SMW's ZeroAct Offers Automated, Zero-Point Workholding

SMW Autoblok’s ZeroAct provides zero-point clamping across many applications, and features optimizations for applications requiring z-axis travel.

Read MoreCNC Indexing & Feeding Partners with Röhm Products

CNC Indexing & Feeding has signed an agreement to act as Röhm Products of America’s manufacturing representative in five states, thus expanding its library of workholding and toolholding solutions.

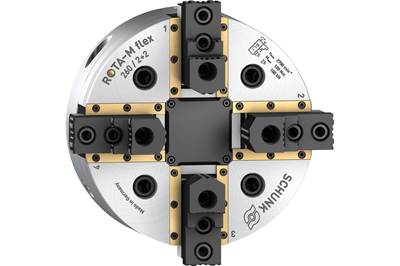

Read MoreSchunk Rota-M Flex 2+2 Maximizes Mill-Turn Flexibility

Schunk’s Rota-M flex 2+2 chuck jaw offers a level of flexibility that the company says is unmatched on the market and covers a wide range of part geometries.

Read MoreDillon Manufacturing Launches New Line of Vise Jaws

Dillon Manufacturing’s new line of vise jaws comes in a variety of materials, blanks and hardnesses, with an option for a wear-resistant Carbinite coating.

Read MoreClamping Solution Facilitates Large-Part Vertical Machining

Mitee-Bite Products’ fixtures demonstrated their powerful clamping support in a project with Akron Gear & Engineering to vertically hold a 1-ton ring during machining.

Read MoreMidaco Hydraulic Docking System Requires No Hoses

Midaco has updated its automatic pallet changer system with a simple-to-use hydraulic docking system that requires no hose management.

Read MoreRoyal Products Releases Free 2021 Product Catalog

Royal Products' free, 168-page 2021 Machine Tool Performance Accessories catalog includes new additions to enhance precision metalworking productivity.

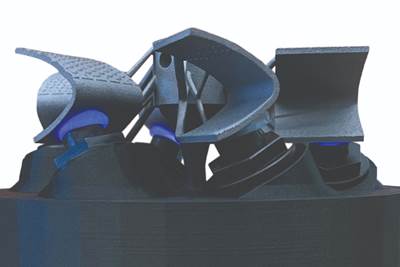

Read MoreChoosing Workholding to Meet Machining Challenges

When it comes to workholding, shops can choose from options that can provide flexibility, help increase throughput and enable five-axis machining.

Read MoreRoyal Products Hires New Regional Business Manager

Royal Products has hired Kendal Glotzbach as its new regional business manager for Indiana and Michigan.

Read MoreSchunk Clamping Force Block Provides Automation Entry Point

Schunk’s Tandem PSG3-LH 100 clamping force block provides a low-maintenance solution for transitioning into automation for basic aluminum and plastics machining applications.

Read More