Milling Tools

Tangential Cutter Speeds Ramping and Plunging

A new high-feed tool extends the benefits of Iscar’s Helitang Upfeed series of tangential milling cutters to include ramping work, as well.

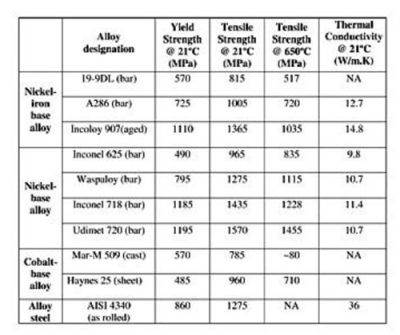

Read MoreCutters Designed for Steel and High-Temp Alloys

The Hi-PosTrio cutting tool line of indexable end mills and face mills features cutter diameters ranging from 0.625" to 6.00" and three insert sizes.

Read MoreA New Milling 101: What Customers Demand

Part 5. For W Machine Works in San Fernando, a custom variation of the WIDIA-Hanita VariMILL II solid end mill proved especially effective in roughing and semi-finishing applications in stainless steels, high-temp alloys, nickel- and carbon-based alloys, and titanium.

Read MoreA New Milling 101: Selecting Tool Materials and Coatings

Part 4. The emergence of new workpiece materials is driving the development of new cutting tool materials and tool coatings. These, in turn, are driving the development of new milling processes and techniques.

Read MoreA New Milling 101: What Milling Is, Then and Now (Plus a Glossary of Milling Terms)

Part 1: Greater understanding of milling tools, what they can accomplish, and the optimum circumstances in which to employ them, is always valuable. The continuing development in milling tools in the face of changing customer requirements, advanced workpiece materials, and the constant need to improve productivity while reducing costs make this even more important today.

Read MoreA New Milling 101: Cutter Design and Application Considerations

Part 2: Cutting tool geometry governs almost all design and application considerations related to various milling choices.

Read MoreSimple Retooling Brings Significant Savings

Changing to Accupro cutting tools from MSC Industrial Supply and adjusting parameters accordingly enabled these shops to realize significant cost savings and productivity gains without fundamentally altering their operations.

Read MoreMold Shop Finds Tool Performance Outweighs Price

This moldmaker sought to reduce costs to compete with low-cost overseas manufacturers. While purchasing relatively expensive, high-performance tools might seem counterintuitive, resulting improvements in cycle time and tool life more than made up the difference.

Read MoreImproving Surface Finish During High Speed Machining

Many factors can affect surface finish. This answer to a reader’s question focuses on imbalance and frequency sensitivity.

Read MoreTool-Related Considerations for More Efficient Machining of Titanium

The expert in our Titanium Machining Zone offers advice related to coolants and coatings.

Read More

.png;maxWidth=300;quality=90)