Machining Centers

The Benefits of Being a One-Brand Shop

This shop finds advantages in having CNC machines from a single builder, but the general strategy has benefits that can be applied to any startup shop.

Read MoreWhat’s Empowering Machining Technology in Power Generation

Shops have many choices to handle large, heavy parts as well as small, delicate parts. Tight tolerances, tough alloys and complex geometry are the challenge.

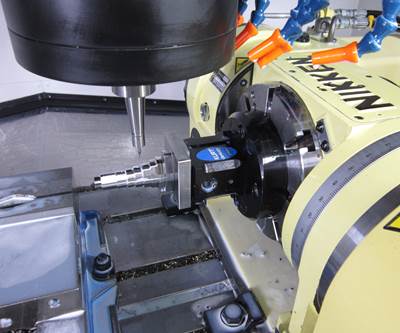

Read MoreFive-Axis HMC Accommodates Complex Geometries, Decreases Setups

Makino’s five-axis A500Z features a fully-integrated “Z-type” fifth axis to accommodate complex part geometry challenges in fewer workholding setups and machining operations.

Read MoreShop Works to get the Most Out of Its Five-Axis Capabilities

Vertical machining centers with rotary tables helped this Indiana job shop set itself apart, but specific machine features and additional equipment have helped it use them more efficiently to grow its business.

Read MoreFive-Axis Line Targets Die/Mold, Aerospace

With so much happening in a busy show year between NPE2018 and Amerimold 2018, MoldMaking Technology is revisiting some of the technology that was on display. In case you missed it: At IMTS 2018, Takumi USA displays its series of five-axis machining centers, which includes the U600 model and the U800 model.

Read MoreKern Precision Partners with Innolite in North America

Kern will now be able to distribute Innolite’s machines, benefiting ultra-precision machine shops with more effective processing.

Read MoreVMC Capable of Heavy, Difficult Cuts without Sacrificing Accuracy

IMTS 2018: Long known for high-speed, high accuracy vertical machining centers, Chiron has developed a new range of VMCs, in twin and single spindle versions, that add extreme stiffness and greater stability to the package, allowing the machines to take heavy cuts in difficult material while maintaining accuracy.

Read MoreVMC's Dual Y-Axis Ballscrews Improve Surface Quality

IMTS 2018: Hardinge has added the Bridgeport V1320 vertical milling center to its Bridgeport V-series line.

Read MoreWith Retention Knobs, Shop Sets Sight on Aerospace Machining

Mitch and Brian Olson didn’t know much about CNC machining when they started their machine shop, but they learned that if they wanted to pursue high-accuracy aerospace work, they would need to overcome a flaw inherent in V-flange tooling.

Read More