Machines

Deep-Hole Drilling Machine for Micro Bores

Auerbach Maschinenfabrik has launched the MTB 100 micro deep-hole drilling machine, developed for diameters ranging from 0.5 to 3.0 mm with a maximum drilling depth of 300 mm.

Read MoreLow-Power, Large-Format Fiber Laser Reduces Operating Costs

Laser Photonics has added the Titan Express to its line of large-format fiber laser cutting systems.

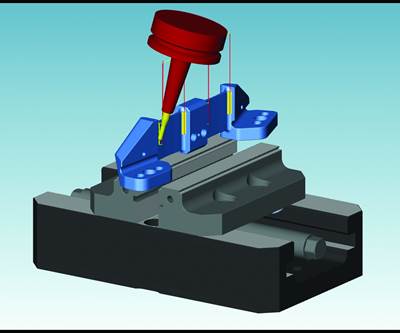

Read MoreWhy a Two-Spindle VMC? Double the Machining Without Double the Footprint

The two-spindle VMC increases output where space and other factors are constrained. With W-axis compensation for Z-height differences, setups don’t have to be perfect to use two spindles in tandem.

Read MoreFiber Laser’s Eco Mode Reduces Costs During Standby

MC Machinery’s fiber laser offering has expanded to include the SR-F series from Mitsubishi.

Read MoreLaser Control Feature Programs, Drills Complex Hole Patterns on 3D Parts

SmartPerf from Prima Power Laserdyne is a laser control feature for programming and drilling simple or complex patterns of holes in linear and cylindrical paths on 2D and 3D parts.

Read MoreCompact Abrasive Waterjet Cuts Most Inch-Thick Materials

Omax’s ProtoMax abrasive waterjet is a compact, self-installed cutting system for prototyping and low-volume cutting of almost any material around 1" thick.

Read MoreHybrid Five-Axis Machine Builds Near-Net Shape Part Features

Smart Manufacturing Experience 2018: Mazak will exhibit its various Smooth Technology products in addition to live cutting demonstrations on its VC-500 AM and small-footprint Integrex i-100 Bartac-S machine tools.

Read MoreMicrocutting Waterjet Makes 0.2-mm Incisions

Water Jet Sweden has launched the Fine Abrasive Waterjet (FAJW) Micro Head Package for its ordinary machine models.

Read MoreBuying a Five-Axis: Selecting the Right Machine

Horizontal or vertical? Trunnion or swivel head? What’s the effective difference between different configurations of five-axis machining centers?

Read MoreCAM Software Helps Shop Five-Axis Machine Aerospace Part

A five-axis machine and HyperMill CAM software from Open Mind Technologies gave a shop the ability to meet the tight tolerances required for the camera-mounting brackets on a NASA satellite mission.

Read More