Laser & Waterjet

New Lasers Are Mainstreaming Micro-Machining

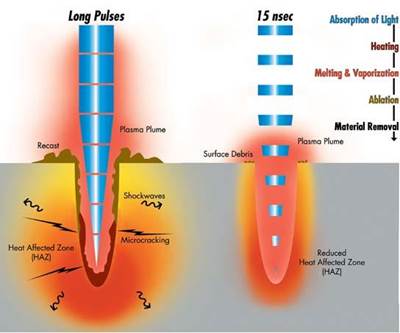

Technical demands from the electronic, medical, aerospace and other industries are pushing the boundaries of micro-machining to smaller and more precise tolerances. The application of laser technology is pacing the demands from industry for smaller geometries and increasingly tighter specifications.

Read MoreFlange Cutting Challenges Overcome With New Waterjet Technology

One challenging application for this Ontario manufacturer has been cutting flanges. Previously, their customers had plasma-cut 1/2 -inch Hastalloy. However, plasma left a heat-affected zone that could be a problem when welding the flanges.

Read MoreNon-Traditional Methods For Making Small Holes

Consider these alternatives when conventional drilling can't do the job.

Read MoreDirect Part Marking Enhances Product Traceability

The ability to mark workpieces is an important service that many job shops and product manufacturers must offer their customers. Marking allows parts to be identified and traced to their origin.

Read MoreWaterjet Cutting Without Abrasives

Soon, industrial users of waterjet metalcutting may be able to cut sheet metal, composites and other materials without abrasives -- or at least with much less abrasive than they're accustomed to using.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)