Horizontal Machining Centers

The In-Cycle Enabler

To achieve 144 hours per week of in-cycle time on its machining centers, this plant relies on software that offers a clear, colorful, real-time view of where the time losses are occurring.

Read MoreMachining Centers Reconsidered

A stable customer relationship gave this shop the chance to fundamentally change its equipment.

Read MoreDifferent Directions In Machining Center Motion

Some machining centers have begun to appear that use resultant motion in less elaborate ways. That is, these machines use the resultant motion of different elements moving in different directions to achieve the motion along X, Y or Z, but they do so within machining center designs that are considerably more like standard machines.

Read MoreHow To Perfect A Machining Process (Or At Least How To Make It More Trustworthy)

Instead of inspecting machined parts, get to know the process better.

Read MoreKeeping Accuracy Within Reach

Part quality is at risk if a machining center cannot hold tolerances at the farthest reaches of its work envelope. This makes volumetric accuracy a key indicator of a machine's performance. One machine tool builder discusses the implications.

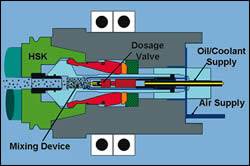

Read MoreUnderstanding MQL

Minimum quantity lubricant can save money, improve tool life and improve the part finish. But it may involve changes to both the equipment and the processing strategy.

Read More

.jpg;maxWidth=300;quality=90)