Horizontal Machining Centers

HMC Reduces Setup Time On Low-Volume Jobs

Producing parts right the first time is especially important for a job shop that pays as much as $10,000 for raw material. Although complex geometries and tight delivery schedules initially made this challenging, a four-axis HMC with pallet changer allowed faster setups and unattended production.

Read MoreHorizontal Leap Helps Shop Change And Grow

Migrating from short-run jobs and prototyping to tackling complex defense compartment components during the past few decades has kept business humming at Proteus Manufacturing. However, increased business led to new production challenges. With a single Kiwa HMC from Methods Machine Tools that can perform the work of three of the shop’s other machines, Proteus has realized substantial cycle time savings and incorporated “lights-out” operations.

Read MoreHMCs Designed For Flexibility

Heller’s full-color brochure features the MCH line of HMCs. a one-piece, cast iron construction and include Siemens 840D CNCs, swiveling pallet changers, rotary indexing tables and more.

Read MoreVMC, HMC For Productive High Speed Machining

The FH400J is the company’s smallest HMC to date. Designed with a 15,000-rpm spindle, the machine is suited for high speed applications. The 2.

Read MoreEntry-Level Factory Automation Solution

The compact Kiwa-Japan KH-41 HMC is 60. 2" (1,530-mm) wide and can handle a variety of workpieces, providing an ideal entry-level factory automation solution, the company says. The HMC has a full rotary B axis and can be installed in the same space as a vertical machine.

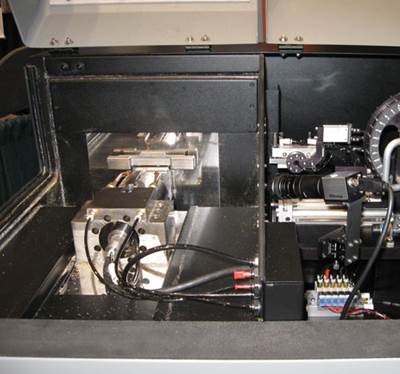

Read MoreA Micro Machine Design

This machine has no toolholders and no tombstone—but there is a camera. Here are details of a machining center designed for micromachining.

Read MoreCompact HMC Provides High Speed, Reliability

The a51 HMC is designed for performance and reliability. According to the company, the simple-to-operate machine is compact, easily maintained and quickly deployable for manufacturing applications that require maximum throughput and dependability. The machine is suited for medium- to high-volume production shops, first- and second-tier automotive parts suppliers and general-contract machining operations.

Read MoreVideo: Horizontal Profiler For Aerospace Machining

An alternative to the typical profiler design, this machine saves labor by allowing chips to fall out of the way.

WatchVideo: 56-Percent Productivity Increase By Reducing Chatter

The video compares a milling pass that chatters to one that is stable. Because the stable speed permits greater depth of cut, productivity increases.

WatchSoftware Supports Cell-Based Production Process

Implementing advanced manufacturing cells can help a shop improve productivity, but the cells themselves may be only part of the solution. That’s the case at Wilcox Industries, which combined advanced manufacturing capabilities of automated machining with the flexibility of Mastercam CAD/CAM software to keep up with continuing growth.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)