Grinding

Hob And Shaper Cutter Aids Sharpening Of Reliefs

Star SU manufactures Sykes-style herringbone cutters and offers tool resharpening machines for sharpening the face and relief lip on the herringbone cutters. The PTG-1 hob and shaper cutter resharpening system includes software for the special relief grinding of Sykes cutters. This five-axis grinding machine features a Num Axium CNC control, Numrotoplus software, integrated automatic part probing, automatic wheel probing, and on-board wheel dressing.

Read MoreConvertible Abrasive Belt Machine

Dynabrade's Dynafile II air-powered abrasive belt machine features a grinding head that pivots 360 degrees, allowing the tool to get into heard-to-reach areas. The machine features a 20,000-rpm direct-drive air motor that powers abrasive belts 1/4" to 3/4" × 18" long. According to the company, the ergonomically designed motor handle has a 7-degree pitch to help prevent wrist and arm fatigue.

Read MoreCut/Grind Combo Wheels Reduce Production Time, Costs

CGW-Camel Grinding Wheels has expanded its high-performance Super Quickie-Cut line with the introduction of 0. 075" cut/grind combo wheels. Using the wheel for both cutting and grinding can reduce production time and cost.

Read MoreMultisurface Grinder For Complex Precision Components

Bryant Grinder, a division of Vermont Machine Tool Corporation, introduces a new modular multi-surface grinding machine with extended flexibility to grind complex workpieces. The LL2U-MS can be configured as a chucker, shoe-type centerless, roll-type centerless and center-type work (between centers). The machine features 10" (255 mm) of Z-axis travel, 10" (255 mm) of X-axis travel and an optional U axis, also with 10" (255 mm) of travel.

Read MoreGrinding Turbine Rotors Has Advantages

For many aerospace components, grinding systems achieve greater productivity than milling and broaching on today’s lighter, tougher, harder materials. Tests performed at Saint-Gobain Abrasives’ Higgins Grinding Technology Center in Worcester, Massachusetts, showed that along with the latest abrasive and bonding technologies, the systems approach produced remarkable results when applied to grinding turbine rotor root-form slots.

Read MoreJIMTOF Report: From the Field

The Japan International Machine Tool Fair (JIMTOF) is Japan’s most important machine tool show. The 2008 show reinforced the trends observed at the International Manufacturing Technology Show (IMTS) that took place in Chicago two months earlier. Along with a review of the show, this article summarizes editorial visits to two new machine tool factories. The report shows that Japan continues to be a dynamic force in machine design and construction.

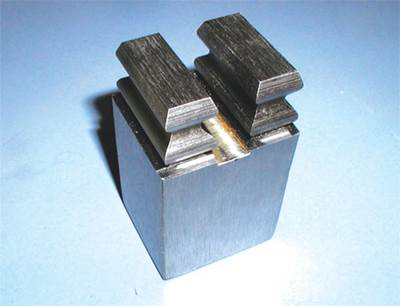

Read MoreFixturing Device Simplifies Squaring

Peter Schmidt of the Hermann Schmidt Company developed a intuitive fixture for squaring blocks for the die and mold industry. The system interfaces well with components from the System 3R catalog and is capable of making a block square within millionths of an inch.

Read MoreFlat Honing Clears Production Hurdles

A shortage of critical bearing components is keeping aircraft out of the sky. This manufacturer combines flat honing with its own expertise to help bearing production really take off.

Read MoreDrill Point Grinders

Cuttermasters’ GSC drill point grinders are designed to regrind drills with diameters ranging from 0. 098 to 1. 032".

Read MoreReplacing Turning with Grinding

This compressor maker’s custom impeller profiles used to present a sticky machining problem. Now, the parts no longer need the wax that turning used to require.

Read More