Data-Driven Manufacturing

Remote Monitoring Anticipates Potential Issues, Prevents Stoppages

Chevalier Machinery USA has launched the iMachine communications system, which enables users to avoid downtime and a loss of productivity.

Read MoreMachine Monitoring Both Challenges and Benefits Shop Culture

How does a shop deal with the “Big Brother” feeling that comes from implementing machine tool data collection? Part of the answer is the benefit to employee experience that this data collection will make possible. Watch video from the Top Shops Conference.

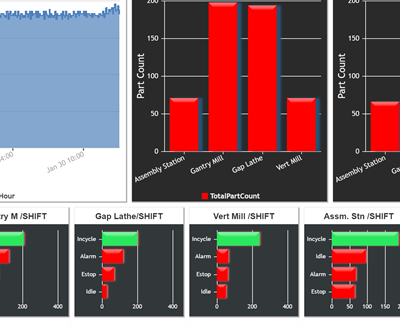

WatchSoftware Captures, Displays Real-Time Machine Data

Smart Manufacturing Experience 2018: Memex presents the new release of Merlin Tempus Enterprise Edition (EE), version 3.5.

Read MoreManagement Software Automatically Administrates Shop Operations

Fastems’ Manufacturing Management Software is a progressive solution for automatic production processing, complete with planning, controlling, visualizing and monitoring capabilities.

Read MoreMonitoring System Connects Control with PCs, Mobile Devices

Heidenhain Corp.’s StateMonitor connects the company’s TNC controls with PC systems to enable users to view data and evaluate control processes remotely and in real-time.

Read MorePlatform Simplifies IIoT Data Management

Smart Manufacturing Experience 2018: The MachineMetrics predictive analytics and machine learning platform enables manufacturers to harness, structure and take action on machine data.

Read MoreTool Identification System Transfers Data Via RFID Tags

Smart Manufacturing Experience 2018: The latest version of Caron Engineering’s ToolConnect retrofit hardware and software package for machine tools is designed to reduce human error and setup time by automating the transfer of CNC tool data to and from the control.

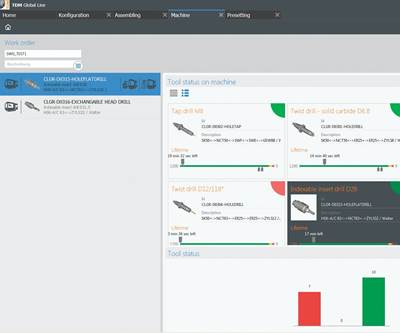

Read MoreConfigurable Software Maps Tool Circulation

TDM Systems has introduced a Shopfloor Manager module that records the entirety of a tool’s circulation, from planning for tool assembly and presetting to tool use at the machine and disassembly.

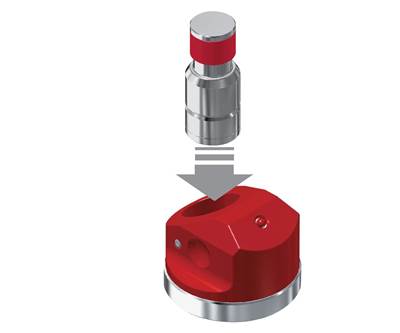

Read MoreMachine Tool Sensors Determine Workpiece, Tool Offsets

Big Kaiser has introduced the Base Master Red and Base Master Mini machine tool sensors.

Read MoreCybersecurity for Job Shops

Small and medium-size machining job shops can take steps to protect computerized or networked assets such as CNC machines from cyber attacks.

Read More

.jpg;maxWidth=300;quality=90)