Cutting Tools

Drilling Solutions Improve Tool Life, Cut Cycle Times

Interruptions due to worn or failed tools can be especially detrimental to productivity, especially on parts with lengthy cycle times. At a manufacturer of large commercial heat exchangers, many of which require drilling of hundreds of holes, the improved tool life of Precision Dormer’s Hydra and CDX-Inox drills led to significant cost and cycle time savings.

Read MoreA Deeply Holistic Approach

In its effort to streamline every step of the mold building process, this company has upgraded its deep-hole drilling capability with a new six-axis machine. A rotary table with magnetic workholding enhances this machine’s flexibility.

Read MoreUniversal Milling Machine For Complex Applications

Suited for vertical milling, drilling and tapping, Knuth Machine Tools USA’s VHF 3 universal milling machine also includes a horizontal arbor for horizontal milling, slotting and keyway cutting. The machine is useful for mechanic workshops, production, training, single-part manufacturing and prototyping.

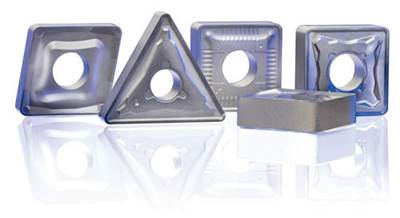

Read MoreSteel Turning Grade Family Expands

Valenite introduces its tough grade, VP5635, to the 5600 series steel turning grade family. For applications such as roughing steels, stainless steels and cast iron, this grade is said to increase production cost savings and lower total production time.

Read MoreHigh-Feed Cutter Features Six Edges

The Power-Feed+ high-feed cutter utilizes a trigonal-shaped insert with six cutting edges designed for performance and economy. The insert was engineered for high speed machining and features strong, heavy edge prep as well as durable, wear-resistant substrates and coatings, the company says.

Read MoreCarbide Edge Preparation Improves Productivity

Tool Alliance’s SmoothEdge edge preparation is available for virtually all Tungsten ToolWorks products. The edge preparation is said to improve productivity, especially on the company’s carbide inserts and solid carbide round tools.

Read MoreWhat Is The Best Way To Machine A Deep, Narrow Pocket In Titanium?

Boeing’s answer to a reader question emphasizes the use of high-feed milling tools.

Read MoreMiniature, Solid Carbide Tool Mills

Emuge’s series of miniature solid carbide thread mills are designed for machining difficult materials such as stainless steels, titanium, K-monel, Hastelloy and Inconel, the company says. The line is suitable for a variety of applications especially those in the medical, aerospace, energy, defense and computer industries. According to the company, the thread mills eliminate the possibility and consequences of tap breakage.

Read MoreIndexable Drill Uses Four Insert Sides

Sumitomo’s WDX indexable drills are designed for large diameter hole drilling. The accurately drill can also perform turning and boring operations, the company says. The drill’s nickel-plated steel body is said to reduce inventory costs by accepting the same insert geometry for both the outer and inner cutting edges and allowing the use of all four of the insert’s cutting edges.

Read MoreHigh Speed Drills Eliminate Exit Burrs

OSG’s Nexus, part of the Vanadium series of high speed drills, features a 40-degree helix and a sharp, thinning point designed to reduce work hardening, improve finish and eliminate exit burrs. The series features WD1, the company’s latest coating technology for drills. Higher oxidation temperatures, better adhesion strength and elevated hardness allow the drills to run faster without shortening tool life, the company says.

Read More