CNC & Machine Controls

Simplifying Operator Responsibilities - Dimensioning Methods

All companies expect quite a bit from their CNC operators. Minimum responsibilities commonly include workpiece load/unload, cycle activation, offset adjustments to hold size, inspections on completed workpieces, and reporting inspection results to the statistical process control (SPC) system.

Read MoreAutomating Milling Machines Expands List Of Machinable Projects

Find out what this manufacturer chose when they decided to automate their milling machines.

Read MoreSoftware Is The CNC

Imagine a computer numerical control (CNC) system set free of proprietary hardware. Two shops discuss their experiences with software-based machine controllers.

Read MoreThe Shop With A Nervous System

Automatically recording and distributing information about what's happening while a machine tool is in operation leads to process improvements and higher productivity for this aircraft manufacturer.

Read MoreDrive Train Facility Moves From Punched Tape To DNC

This Rockwell plant measures 200,000 square feet, employs a staff of 460 and is primarily involved in the production of drive shafts for semi-trucks. As the product line evolved, so did their manufacturing methods.

Read MoreAcu-Rite Reinvents Its Products And Its Processes

It's a brave company that makes the commitment to obsolete its current product line and bring on-line a new one. As of September first, that's exactly what Acu-Rite (Jamestown, New York) will do. A leading manufacturer of digital readouts (DRO) for thirty years, the company decided in 1995 to begin a process that would replace the entire product line in a single stroke.

Read MoreOpen-Architecture CNC Closes Servo Loop In Software

The company developed Compact II, an NC programming language that quickly became one of the most widely used in the metalworking industry.

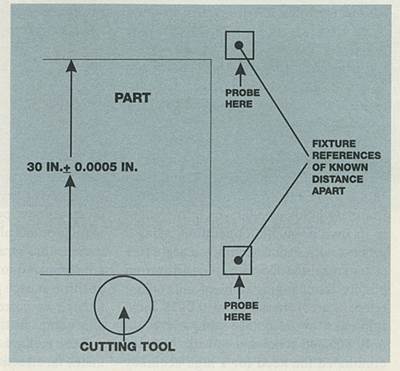

Read MoreBreak The Accuracy Barrier

"Reference comparison" uses probing to hold accuracies tighter than inherent process error.

Read MoreKey CNC Concept #4—The Forms Of Compensation

Though applied for different reasons on different machine types, all forms of compensation allow the CNC user to allow for unpredictable conditions related to tooling.

Read MoreKey CNC Concept #2—Know Your Machine

If you already know basic machining practice as it relates to the CNC machine you will be working with, you already know what it is you want the machine to do.

Read More

.jpg;maxWidth=300;quality=90)