Basics

3D Printing Jigs and Fixtures for a Reliable, Cost-Effective Factory Floor

Register for this free webinar on how to successfully implement 3D printing to produce reliable factory floor jigs and fixtures. (Sponsored Content)

Read MoreHow to Get Form Measurements Right, Part 1: Recognize the Source of Errors

Recognize the source of setup errors.

Read MoreFour Questions a Shop Considering HMCs Should Ask

Compared to vertical machining centers, horizontal machining centers offer the potential for improved spindle uptime, cycle times and throughput. Although they come with a higher price tag, their higher productivity can be significant to shops of all sizes, as Valley Tool has experienced.

Read MoreAfter the Build Is Done Why Do the Bills Keep Coming?

When your additively manufactured part is done printing, you just pull it out of the machine and start using it, right? Not even close.

Read MoreWhy Five-Axis Machining?

There are several perks to taking advantage of today’s five-axis machining technology. So, what holds job shops back from upgrading? Here are some of the justifications. (Sponsored Content)

Read MoreUpcoming Webinar: 5 Steps to Successfully Monetize Your Shop Floor Data

Register for this free webinar on how to successfully leverage data-driven manufacturing. (Sponsored Content)

Read MoreIndexable Milling Tools for Driven Tool Stations on CNC Turning Centers

As the milling capabilities of CNC turning centers improve, so too must the cutting tools. Here’s how to get more out of the live tooling on your turning equipment.

Read MoreThree Emerging Technology Trends to Look for at IMTS 2018

Not only a display of products, IMTS is an introduction to never-before-seen technology, particularly those on the horizon. Here are a few of the top emerging technology trends and how to find them at IMTS 2018.

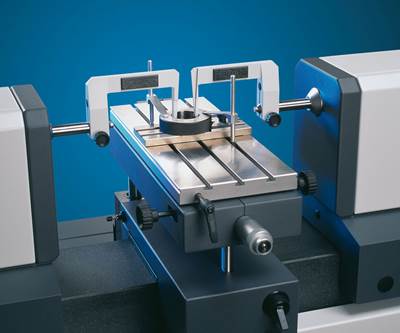

Read MoreThe Art of Submicron Measurements

Special attention must be paid to the selection of the gage and readout as well as to mastering.

Read MoreHow to Deal with Complexities That Affect Worker Skill Levels

The goal must be to keep tasks as simple as possible for those who perform them.

Read More