Which Five-Axis Machining Center is Right for You?

Sponsored ContentWith so many choices in five-axis machining technology, how do you know which is best for your shop? First, consider the parts. Then, look at existing processes and potential five-axis benefits.

Share

There are plenty of reasons to take advantage of today’s five-axis machining technology. First, it gives you access to all five sides of a prismatic workpiece. If for no other reason than being able to eliminate additional setups or processes, this technology can be justified in a wide range of applications, and at a surprisingly affordable cost. As the parts get more complex, the payback increases with the ability to generate intricate workpiece features or contours that cannot be machined efficiently, or at all, with a conventional three-axis machining center.

But with so many ways to go about five-axis machining, how do know what is the best buy for your shop? DMG MORI’s general manager of Aerospace Center of Excellence, Jeff Wallace, offers some insight.

With some 47 models of five-axis machines in a variety of configurations, he says, DMG MORI is well-positioned to address the transition to increasingly sophisticated five-axis machining technology. Whether you’re looking to introduce five axes for the first time or need higher machining capacity, there are a wide variety of options to consider.

Why Five-Axis Machining?

Some people mistakenly think five-axis technology is only for the most complex parts. While it certainly excels at that, a significant majority of the applications are simply used to enable the machining of five sides of a workpiece in a single setup. With three-axis machining, jobs might require two, three or more setups to get at all the features of the part. With the done-in-one approach, those additional setups are eliminated in addition to potential for error each time you reposition a part. The justification for a five-axis machine on these grounds is simple, with dramatic reductions in total setup, machine time and reduced fixturing.

Check out the monoBLOCK series.

Another inherent advantage of five-axis machining is it can use shorter tools because the tool/toolholder combination can be tipped away from otherwise interfering surfaces or features on the workpiece. This is particularly important in die and mold work where the use of toolholder extensions is common to reach deep cavity surfaces. A shorter tool results in less vibration, allowing for heavier or faster cutting, better surface finish and longer tool life.

Particularly for job shops, five-axis machining enables complex parts to be cut from solid material that otherwise might have to be cast. This enables quick turnaround for short-run and prototype work on high-value parts. It’s a great opportunity to differentiate the shop from lower tech competitors and build a more profitable business.

Five-Axis Technology that Fits the Part

First, consider your parts. How big are they? How much do they weigh? What levels of accuracy do they require?

For example, if the parts are small to medium size, with today’s technology, a tilting-table-type machine is going to be the best bet. If the parts are large and heavy, an articulating head—possibly on a gantry-style machine or a horizontal machining center—may be the only option. This consideration alone will narrow your choices and help you compare features of various machine models within the required range.

Starting with 3+2 Machining Centers

The simplest and least expensive way to get at five sides of a part is with a 3+2 machine configuration. For small to medium machines, that typically means a three-axis machining center with a tilting rotary table to position the part. This of course can be accomplished with an auxiliary two-axis table on a standard three-axis machining center. But a machine with an integrated tilt table offers better machining performance and is easier to set up and program.

With a 3+2 machining center, the fourth and fifth axes are locked down while the part is machined. Still, almost any plane of the workpiece can be presented to the spindle, and surprisingly complicated parts can be cut efficiently.

In DMG MORI’s case, a swivel rotary table is integrated into the CMX U series of 3+2 machines. With a C-frame construction, Wallace says, these universal machining centers also allow the spindle to be set in a vertical or horizontal orientation.

Moving Up to Full Five-Axis Machining

The next step up is adding full simultaneous contouring control to an otherwise similar machine configuration, represented by DMG MORI’s DMU duoBLOCK series. The primary advantages of full five-axis control are that you can now dynamically tilt the tool into the cut, away from interference zones, or keep the tool vector constant as it feeds across sloped or free flowing surfaces. These are the reasons why five-axis machining is so widely used for aerospace components, orthopedics and other parts with curving features.

For several other kinds of parts, five axis facilitates more efficient use of cutting tools. Tilting the cutter relative to the workpiece surface supports better utilization of the milling flutes, often cut with the side rather than the end of a cutter.

Aided by advanced control software, five-axis machining centers have become a flexible and productive option for gear generation.

For this is the DMU 50 also a good example. The machine combines more than 20 years of experience, proven technology and low investment costs in the 5-axis portfolio of DMG MORI. On this basis and enhanced in all respects the bestseller has moved into the next round. This compact DMU 50 3rd generation sets new standards in 5-axis to 5-axis simultaneous machining. With its extended swivel range, more powerful spindle and its innovative cooling concept the machine guarantees a competitive edge in a range of industries.

Moreover, with a 3-axis process, there is little alternative to the ball nose end mill to generate contoured surfaces. To get a smooth surface requires multiple passes with very small step-overs, which takes a lot of machine time and may still require another secondary process to smooth the cusps. With five-axis machining, you can even use a flat nose end mill to generate some of the contoured surfaces. In a process sometimes referred to as “sturtz milling,” the tool is tilted into the cut presenting the radius of the tool to the surface of the part.

The ability to access more features of a part is simply more pronounced with full five-axis control, as the tool can dynamically tilt away from interference zones on the part. Full five-axis control provides the opportunity to detail hard-to-reach features—such as the corners of pockets or bosses—and create smoother surfaces in the process. This capability can eliminate the need for secondary processes, such as sinker EDM in die and mold work.

Higher Precision and Production

Higher part precision requirements in production environments place higher demands on a machine’s construction and motion control system. Rising to these demands, DMG MORI’s NMV series is a vertical machine with the column (X and Y axes) traveling overhead in a “box-in-box” construction.

Today’s higher performance five-axis machines can generate very complicated parts quickly and precisely.

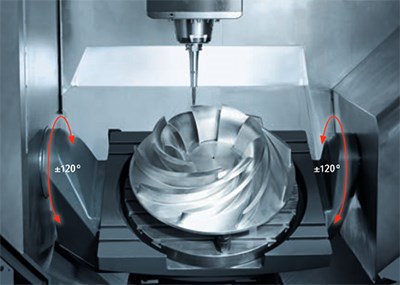

Critical to this machine’s performance is the use of direct drive motors on the B and C rotary axes, which sometimes can be a restriction if there is a high demand for rotary acceleration and deceleration during the machining process, such as in the manufacturing of blisks or impellers.

Firstly, direct drive servos are faster, with over 50 RPM on B (tilt) and up to 1,200 RPM on C axis with optional turning. Direct drive motors also eliminate the backlash often seen in most gear-driven systems. The machine spindle on the NVM machines is also direct drive, which provides full power across a wider speed range and better acceleration/deceleration rates.

Secondly, the machine’s ram is octagonal in shape, with four guideways located diagonally from each other, “capturing” the ram in the middle. Wallace says this design controls thermal displacement and results in better damping of vibration.

Another five-axis machining platform option is DMG MORI’s DMU monoBLOCK series. This machining platform series offers a wide variety of options so that machines can be better configured for multiple applications. It can achieve even higher levels of precision with a cooling system that covers the servo motors and mounts, the C-axis gearbox and an internally cooled X-axis ballscrew. The machine features a multi-sensor system feeding a real-time control system that can compensate for small errors caused by thermal conditions, workpiece inertia, or other physical factors.

Even though this machining center series uses a tilt table design, it can handle surprisingly large workpieces. With a trunnion-style table supported and driven at each end, the largest model can handle workpieces up to 13,228 lbs. with X-Y-Z travels of 52.6" × 49.2" × 35.4". It can even be equipped with a higher speed table that permits vertical turning and five-axis machining on the same machine.

With the ability to integrate with automation features—such as a six-pallet changer—this five-axis machine series is used across a wide range of industries such as aerospace, automotive, energy, medical, mold making and more.

Better Processes AND Faster Programming

What still scares many people about five-axis machining is the part programming. However, CAM systems have evolved in recent years and become much easier to use. These systems include features where programmers can create five-axis toolpaths and still work largely within the 3-axis context in which they are accustomed. As a result, shops can employ familiar cutting strategies augmented by the additional workpiece features that five-axis machining provides.

Five-axis technology cycles aid with programming complex parts such as impellers and blisks.

A "powerful machine tool" cannot be defined by the machine itself anymore. In the current IoT movement, software is a major factor to improve operational efficiency and production.

Correspondingly, as the number of machine tools increases, it is important to build an efficient centralized machine control by utilizing the latest network technology.

The CELOS control does that and also goes a long way to ease and improve the programming process. Actually, CELOS is not itself a CNC, but an HMI (human machine interface) that DMG MORI uses on all its machine tools, regardless of the CNC brand – Fanuc, Siemens, Mitsubishi or Heidenhain. DMG MORI does this not just to bring familiarly to operators working on multiple machines, but also to pack more process knowledge in the control to allow complex routines to be executed without extensive expertise required of part programmers or operators, which becomes all the more important with 5-axis machines. These “Technology Cycles” are essentially preprogrammed routines that apply best practice techniques while also resulting in substantial reductions in programming time. There are 34 of these routines covering a wide range of operations:

- Handling Cycles aid part- and tool-oriented functions such as adjusting feed rate relative to table load, automatically sorting tools to minimize magazine indexing time, and more. There is also a cycle for B-axis plunging that automatically looks for tool interference which can be a danger point with big parts and long tools.

- Measuring Cycles include the ability to recheck and adjust volumetric accuracy of the machine as well as 4th and fifth axis kinematics, tool scanning, and workpiece measurement.

- Machining Cycles include a module just for 5-axis milling and turn/mill with intelligent look-head, gear generation, and grinding. Automatic Tuning Cycle can adjust machining parameters based on user selectable requirements on speed, surface finish and accuracy. There are also a fleet of cycles for DMG MORI’s turning and multitasking machines.

For safety, the CNCs automatically check for interference in 3D for spindles, tables, tools, workpieces and fixtures. Once a problem is detected, the machine will stop operation, whether it is in automatic or manual mode.

Pre-engineered Automation

With the investment in 5-axis machining technology, it’s important to consider how to make that equipment as productive as possible. For this reason, workpiece and pallet handling options are increasingly being applied to these machines. DMG MORI offers a variety of these options that are pre-engineered to work without having to go through a complicated integration process.

Pre-engineered automation such as the PH series pallet changers allow users to get greater return from their machining investment.

Automation also addresses the shortage of skilled labor most shops face today. It renders five-axis machines capable of running significant hours with very little tending required, making the most of shops’ investments in both technology and people.

Unattended machining is further enabled by the new DMG MORI Messenger which provides access to detailed real-time machine condition information. Messenger allows operators to monitor machines remotely. It also compiles data on when machines are, and are not, in operation and what caused work stoppages. This is actionable information that can help a shop significantly increase spindle utilization regardless of whether machines are running unattended or not.

View a PH 150 on a CMX 70 machining center.

Take a Look

Whether you think five-axis machining isn’t for your shop or you’re satisfied with ten-year-old technology, it’s time to take another look. To help visualize which type of machine tool might be best for your shop, browse DMG Mori’s Machine Selector, where you can search by technology type, control and size.

Contact DMG MORI for more information on products and services.

.jpg)