Automation

Edge Technologies Rebel V-65 Servo Features Small Footprint and Large Magazine Capacity

Westec 2019: Edge Technologies’ Rebel V-65 Servo short bar loader features a 5- to 65-mm diameter capacity for feeding spindle-length round, square, hexagonal and shaped barstock into CNC lathes.

Read MoreFastems' RoboCell One Automates Two Machines at Once

EMO 2019: Capable of automating as many as two lathes or milling machines, Fastems’ RoboCell One is designed for workpieces weighing up to 176 lbs (80 kg) within batches of different sizes.

Read MoreMake Smart Factories Even Smarter with Metrology Data Management

Bringing all of a plant’s quality data into a single digital system will reduce data entry errors, increase efficiency and improve overall product quality.

Read MoreZeiss Completes Steel Portion of New Facility

The new setting will provide an advanced digital infrastructure to demonstrate quality assurance insights for customers and demonstrate smart factory capabilities.

Read MoreFastems RoboCell One Manages Two Machine Tools Simultaneously

The Fastems RoboCell One is designed for handling heavy workpieces weighing up to 176 lbs. (80 kg).

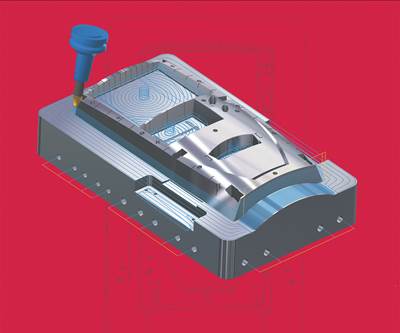

Read MoreMastercam 2020 Streamlines Machining from Setup to Completion

CNC Software has released Mastercam 2020, which increases machining productivity and reduces production costs with 2D as well as multi-axis milling automation features, CAD and model preparation improvements, improved machine configuration, and 3D tooling.

Read MoreTackling the Aerospace Supplier’s Dilemma: Scalability

Automation and robotics can go a long way toward increasing capacity and growing a business dedicated to aerospace manufacturing. But Trinity Precision has learned that refining the indirect and unseen aspects of its operations can be just as valuable.

Read MoreCan Vision and Artificial Intelligence Make Every Robot Collaborative?

That is the aim of this Boston-area startup. Last year, it came to market with technology to make even fast and powerful industrial robots safe to approach. The technology promises to eliminate the need for guarding around them — safety measures that might not be as safe as you think.

Read MoreMitsubishi Electric's Integrated Machine Analytics App Monitors Multiple Machines

Mitsubishi Electric Automation’s Integrated Machine Analytics (IMA) mobile application allows users to monitor their CNC machines through MTConnect, an open standard that makes universal equipment connectivity possible.

Read More3 Mindset Changes for Lights-Out CNC Machining

Expanding capacity into the unattended hours calls for counterintuitive new ways of thinking about the work.

Read More