Innovative Approach Drives Software, Employee Development

During CNC Software's 30th anniversary celebration, MMS Editor Emily Probst got a chance to tour the facility and get a brief glimpse into the company culture.

Share

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

There’s a reason CNC Software Inc. is celebrating its 30th anniversary this year. During a recent tour of the developer’s facilities, I learned more about Mastercam (the company’s CAD/CAM software) and I got to take a brief peek into the company culture as well.

The well-established company has grown in the last 30 years. Its 53,000-square-foot building in Tolland, Connecticut employs more than 140 people, and the company also has international offices in Switzerland and China as well as an educational office in Gig Harbor, Washington.

Looking forward to the next 30 years, CNC Software has developed new products to address recent market trends. For example, President Mark Summers says the company has seen an uptick in multitasking machining. To satisfy this demand, Mastercam X7 includes Mastercam Mill-Turn, which is designed to simplify programming on complex multitasking machines. Gary Hargreaves, VP of business development, adds that X7 also includes a five-axis oscillating toolpath for composites, a new market for growth. The precision turning industry is also on the company’s radar, and Mastercam Swiss Expert addresses this market.

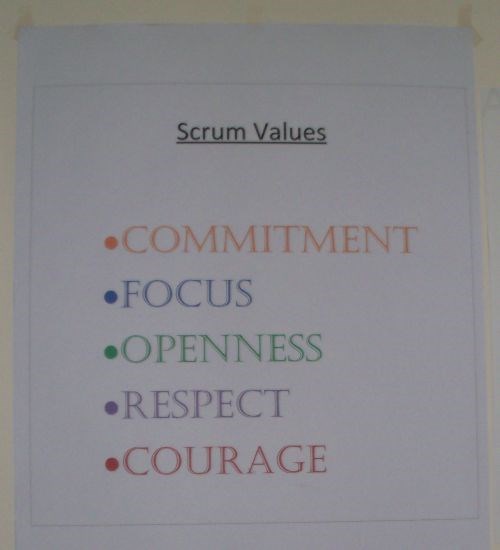

To continue innovating new software releases, the company has adopted a Scrum methodology. Using this approach, employees are broken into teams that work in two-week “sprints” to complete a project. The groups meet daily for a couple minutes to discuss what they accomplished the day before and what they plan on achieving that day. Mr. Hargraeves says this methodology helps the company plan more accurate releases, develop higher-quality products and react to problems quicker.

Aside from developing software to stay on top of manufacturing trends, brothers Mark and Brian Summers take pride implementing sustainable environmental practices. For instance, energy efficiency is a high priority for the company. A 73-kw solar array produces 30 percent of the company’s power, and geothermal is used to heat and cool the building. Not only that, but they’ve located their server room in the basement so it takes less energy to keep cool.

While environmental stewardship is important to the company, employee satisfaction is equally, if not more so. To help employees stay healthy, the facility features a gym with a basketball and racquetball courts, a room to fix and store bicycles, a community garden and a walking trail. Many employees even have adjustable desks that enable them to both sit and stand while working.

Related Content

-

Workholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

-

Inside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

-

DN Solutions Responds to Labor Shortages, Reshoring, the Automotive Industry and More

At its first in-person DIMF since 2019, DN Solutions showcased a range of new technologies, from automation to machine tools to software. President WJ Kim explains how these products are responses to changes within the company and the manufacturing industry as a whole.

.png;maxWidth=150)