Indexable Inserts from Powder

During the 2013 edition of its biennial “Technology Days” event, Horn treated the press to a tour of its entire manufacturing operation. Here are a few highlights.

Share

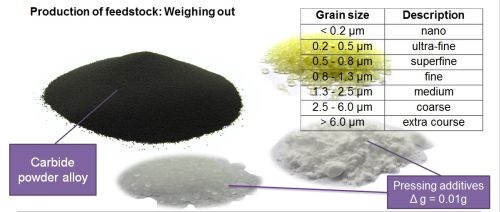

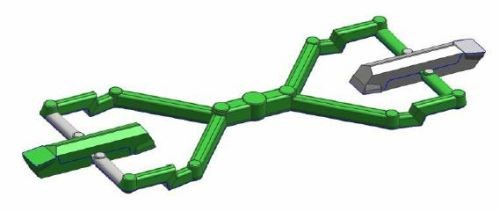

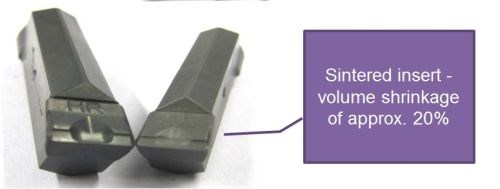

One of the more fascinating aspects of a recent trip to visit Horn in Tubingen, Germany was getting a first-hand look at how the company transforms a powdered mix of various elements into hardened inserts capable of cleaving through even the toughest metal. Click through the picture gallery below to follow this process from start to finish.

Related Content

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

-

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

.png;maxWidth=300;quality=90)