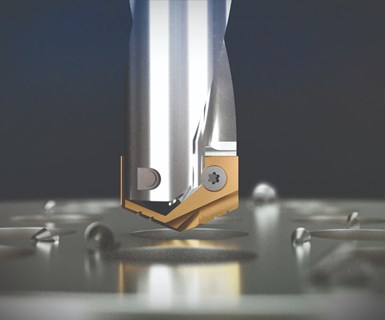

YG-1's SV-Point Spade Drill Enables Higher Feeds and Speeds

YG-1’s SV-Point spade drill inserts are said to provide longer tool life at higher spindle speeds and feeds than conventional spade drills.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

YG-1’s SV-Point spade drill inserts are said to provide longer tool life at higher spindle speeds and feeds than conventional spade drills. The inserts are designed for a range of applications and materials including steel, stainless steel and cast iron.

The SV-Point’s H-Coating offers high heat and wear resistance. Sinusoidal thinning edge enables smooth cutting and improves centering, while a positive rake angle improves hole finish. Imparting low thrust force, the tool is an effective option for underpowered machines, the company says.

Three material options are available, including:

- Super Cobalt (T15), designed for improved tool life and performance compared to standard high speed steel inserts, with a size range of 9.5 to 114.3 mm;

- Premium Cobalt (M48), providing extended tool life compared to T15 in harder materials, with a size range of 9.5 to 114.3 mm; and

- Carbide C5 (P40), designed for longer tool life and faster speeds and feeds in rigid setups, with a size range of 9.5 to 47.6 mm.

Related Content

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

-

High-Feed Machining Dominates Cutting Tool Event

At its New Product Rollout, Ingersoll showcased a number of options for high-feed machining, demonstrating the strategy’s growing footprint in the industry.

-

Selecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.