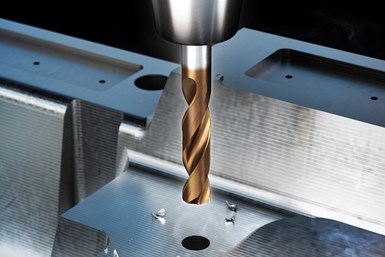

YG-1's Dream Drills Pro Optimized for Steel, Cast Iron

The Dream Drills Pro tools are made with micrograin carbide for core strength and longer tool life, and feature the company’s wave-shaped cutting edge to reduce cutting forces.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

YG-1 has beefed up its Dream Drills line-up with the new Dream Drills Pro line, which is optimized for machining in steel and cast iron. According to the company, the main advantages of these tools are increased cutting speeds and tool life.

The Dream Drills Pro tools are made with micrograin carbide for core strength and longer tool life. They also feature the company’s wave-shaped cutting edge to reduce cutting forces, and a wide-flute design optimized for faster, reliable chip evacuation. A self-centering 140-degree point angle reduces torque and extends tool life.

YG-1’s silicon-based, nano-layered Z-Coating technology gives cutting edges high hardness and heat resistance to improve tool life, while producing good surface finishes and a high number of parts per tool. The tools come in drilling depths of 3×D to 5×D.

Related Content

-

How to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

.png;maxWidth=300;quality=90)