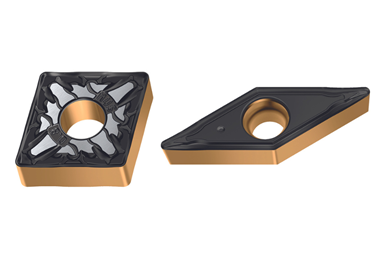

Walter Turning Grades Reduce Machining Times

The WKP01G and WPP05G grades are ideal for continuous cutting and occasional interrupted cuts in high-tensile materials.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View MoreWalter’s new TigerTec Gold WKP01G and WPP05G grades are tailored for maximum performance when turning high-alloy, high-tensile strength steels. According to Walter, the turning inserts can reduce machining time from 20% to 30%.

Walter developed the WKP01G for finishing high-tensile steel and cast iron (ISO P01 and K01 workpiece groups) at the highest cutting speed. The grades feature a hard substrate that provides the highest flank wear resistance, while the multistage post-treatment process produces a smooth rake face to reduce friction and improve toughness. A sharp cutting edge with thinner chemical vapor deposition (CVD) coating provides precise chip breaking for finishing operations.

The WPP05G grade is designed for medium and rough turning of steels at the maximum cutting speed. The substrate is made of a carbide with the highest hot hardness, making the insert suitable for both dry and wet-machining, and highest crater as well as flank wear resistance.

Both grades feature the TigerTec Gold coating technology. The multilayer, medium-temperature titanium carbo-nitride (MT-TiCN) coating is said to improve the elastic property of the highly aligned crystals, which do not detach from the substrate like a conventional TiCN coating to offer more wear resistance. The coating increases toughness and resistance to the flank face. In addition, the coating on the WPP05G grade has a highly textured aluminum oxide (Al2O3) coating to minimize crater wear. According to Walter, the coating increases tool life by up to 50% on average.

Both WKP01G and WPP05G grades are ideal for continuous cutting and occasional interrupted cuts in high-tensile materials (approx. 280-410 HB or 130-200 ksi). Ideal applications include large-scale production of components for the automotive and energy industries, such as gearboxes, gears and rotor hubs, as well as forged shafts for general mechanical engineering and wheel sets for the rail industry.

Related Content

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

-

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

-

Selecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

.png;maxWidth=300;quality=90)