Walter Milling Inserts Feature PCD Cutting Edges

The PCD inserts are suitable for milling a variety of nonferrous workpiece materials, such as aluminum, aluminum-silicon alloys, magnesium, magnesium-based alloys, plastics and fiber-reinforced plastics.

Share

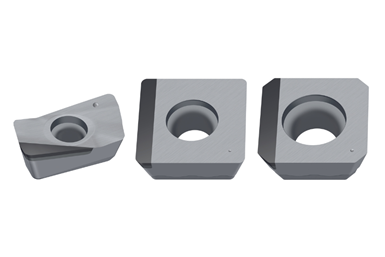

Walter USA has introduced indexable inserts with brazed polycrystalline diamond (PCD) cutting edges for the Xtra·tec XT M5130 shoulder milling cutter and most M4000 milling cutters, including the M4003 face milling cutter.

The PCD inserts are suitable for milling a variety of nonferrous workpiece materials, including aluminum, aluminum-silicon alloys, magnesium, magnesium-based alloys, plastics and fiber-reinforced plastics. Applications include automotive, aerospace and general mechanical engineering. Aviation in particular uses wrought alloys made of aluminum.

According to Walter, the new PCD inserts impart the finest surface finishes while shoulder, face and slot milling. The tools enable precise machining with reduced cutting forces and minimal vibration tendencies. In addition, the PCD inserts provide the shortest machining times due to their ability to mill at high cutting speeds. The inserts can be used dry, with emulsion of minimum quantity lubrication (MQL).

The BCGT090304R-B85 WDN20 and BCGT120408R-B85 WDN20 positive rhombic inserts have one PCD cutting edge per insert and are for the Xtra·tec XT M5130 shoulder milling cutter.

The SDGW09T304-A88 WDN20 and SDGW120408-A88 WDN20 positive-square inserts are equipped with a single-edge PCD cutting edge. These system inserts with corner radius are for most M4000 milling cutters. The SDGW09T3AZR-A88 WDN20 positive-square insert uses a single full-edge PCD cutting edge, and in some applications two corners may be used. It is designed specifically for the M4003 face milling cutter from the M4000 series.

Related Content

-

Emuge-Franken End Mill Wins ANCA's Tool of the Year Award

Emuge-Franken received the award for its specialized tool based on the new Cera-Cut end mill design.

-

Sandvik Cormant's End Mills Eliminate Machining Chatter

The company’s CoroMill Dura line of solid end mills has been extended with aluminum-specific tools.

-

Walter Ceramic Inserts Enable Efficient Turning, Milling

Suitable turning and milling applications of the WIS30 ceramic grade include roughing, semi-finishing and finishing, as well as interrupted cuts.