Walter Launches Profile Milling Cutter

Walter launches the Xtra-tec XT M5460, a profile milling cutter that delivers precision and tool life.

Share

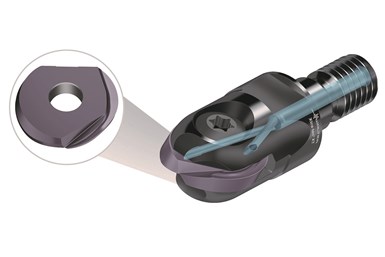

New Walter Xtra-tec XT M5460 profile milling cutter. Photo credit: Walter USA

Walter introduces the Xtra·tec XT M5460, a profile milling cutter designed for maximum precision, tool life and surface quality in precise machining of freeform surfaces and deep cavities.

This profile milling cutter provides an internal coolant channel, enabling chip evacuation using compressed air or MQL. This is necessary for deep pockets as it allows the user to evacuate the chips.

The Xtra·tec XT M5460 is specially designed for difficult materials, particularly for hard machining of steels up to 63 HRC. Alongside Walter’s P3201 and P3204 indexable inserts, Walter offers these strong inserts in its newest grade WHH15X for hard machining. In field tests, the M5460 paired with this latest grade, WHH15X, achieved increases in tool life up to 500%, according to the company.

Walter says this profile milling cutter is effective with steels, cast irons, stainless steels and hard materials. On top of the mold and dye-making advantages, it also offers benefits for the aerospace and energy industries with its high productivity, maximum process reliability and cost effectiveness.

Walter offers the Xtra·tec XT M5460 with both Weldon and cylindrical shanks. Additionally, it is offered with the industry standard cylindrical modular interface. On launch, the new milling cutter will be available with diameters between 3/8-1 in. and between 8-32 mm.

Related Content

-

Going Hands-On with Heidenhain and Acu-Rite Solutions

Heidenhain and Acu-Rite Solutions are offering several hands-on experiences at their booth this year, as well as internal components that reduce energy use.

-

SMW Autoblok Workholding, Automation Solutions Optimize Milling, Grinding Operations

IMTS 2024: SMW Autoblok presents the WPS XL for milling, measuring and grinding operations with five-axis and large part workpieces, as well as several products from its electronics and automation line.

-

Chiron Group Unveils Virtual Showroom & Live Demos at IMTS 2024

Chiron Group combines the best of both worlds at IMTS 2024, featuring live demonstrations of their Micro5 and Mill 2000 machines, alongside a cutting-edge virtual showroom. This innovative approach allows visitors to explore Chiron’s full product lineup without the logistical challenges of transporting large equipment.

.png;maxWidth=300;quality=90)