Walter Launches New Line of PVD-Grade Carbide Milling Inserts

This new grade is now reportedly capable of 30% greater performance in stainless steels and heat-resistant super alloys, and up to 75% greater performance in steels than comparable grades.

Share

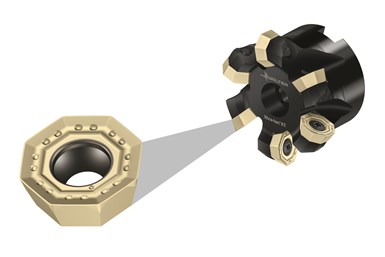

Walter USA introduces its Tiger·tec Gold physical vapor deposition (PVD) grade WSP45G, a new generation of indexable carbide inserts for milling that dramatically expands capabilities for slotting, shoulder and copy milling. The new grade can efficiently process demanding machining applications such as interrupted cuts and difficult materials.

This new grade is now reportedly capable of longer tool life, greater reliability and approximately 30% greater performance in stainless steels (ISO M) and heat-resistant super alloys (ISO S), and up to 75% greater performance in steels (ISO P) than comparable grades. With the launch phase now complete, the PVD-grade WSP45G Tiger·tec Gold can be used universally in all standard Walter milling cutters.

According to Walter, the key to the grade’s performance is its next generation coating technology and its special layer structure. The gold-colored ZrN top layer is said to facilitate exceptional low-friction characteristics as well as excellent wear detection, thus making it possible to utilize the full potential of the indexable insert to extend tool life. Next, multiple layers of aluminum oxide (Al2O3) increase the inserts temperature resistance.

All are applied on top of a TiAlN base layer and a premium carbide substrate as a foundation, greatly increasing the overall wear resistance. These properties make the new inserts ideal for challenging conditions, such as interrupted cuts, long overhangs with a tendency to vibrate or wet machining.

Related Content

-

Custom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

-

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)