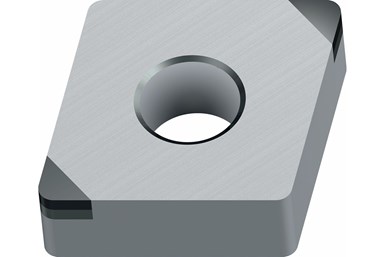

Walter Insert Designed for Interrupted Cuts, Hard Materials

The CBN-grade insert WBH30 boasts 65% CBN content, which helps offer wear resistance in hardened steel.

Share

Walter has introduced the CBN-grade WBH30 insert for hard turning in interrupted cuts. The new grade is designed to offer reliability. The company says its toughness is caused by a good distribution of mixed CBN grain sizes. It offers chemical stability derived from a TiN binder meant to prevent crater and flank face wear. It also provides wear resistance in hardened steels due to the 65% CBN content.

Additional improvement in surface quality and stability can be realized with the advanced wiper geometry option. Walter’s WBH30 CBN-grade inserts are available with and without MW wiper geometry, and with a negative T-land chamfer for optimized strength in interrupted cuts.

WBH30 is the latest addition to the Walter family of CBN grades, which the company says are engineered to tackle the toughest machining challenges. Other grades include WBH10C, WBH10 and WBH20 for turning of hardened steel up to 65 HRC. These grades are designed to deliver a high-quality surface finish and long tool life.

.JPG;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)