Walter Drilling Inserts Provide Extended Tool Life

The P6006 indexable inserts are said to be ideal for holemaking without a pilot drill up to 10×Dc.

Share

Walter USA has announced an expansion of the range for its P6006 indexable inserts for exchangeable-tip drills. The P6006 can be used in Walter’s exchangeable-tip drills, including D4140, D4240 and D4340. Drilling from solid material and stacked plate (laminate) drilling is possible with the D4140 indexable drill insert.

The primary application for the inserts is drilling low carbon, or unalloyed steels (ISO P workpiece group), specifically with low hardness range of 300HB or lower. The secondary application is for drilling non-ferrous metals (ISO N workpiece group). Areas of use include the general mechanical engineering, energy, automotive and aerospace industries.

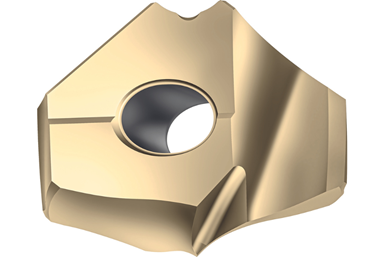

Ideal for holemaking without a pilot drill up to 10×Dc, the inserts provide time savings that boost productivity, according to the company. The inserts were designed to achieve maximum tool life in stable machining conditions due to the wear resistant WPP25 grade with high-power impulse magnetron sputtering (HIPIMS) technology. The grade features a hard, robust substrate to extend tool life. The inserts feature efficient chip breaking, a high level of centering accuracy and the ability to impart the finest surface quality and optimized wear detection because of the smooth, gold-colored top layer.

The inserts feature a new type of geometry with a 140-degree point angle. The sharp cutting edge, in connection with a positive rake angle, reduces cutting forces. The tools also feature the signature 100-degree prismatic base for the contact point in the body and a corner-protection chamfer. Walter offers the P6006 indexable drill inserts for diameters of 12.00-37.99 mm (0.472-1.496").

Related Content

-

High-Feed Machining Dominates Cutting Tool Event

At its New Product Rollout, Ingersoll showcased a number of options for high-feed machining, demonstrating the strategy’s growing footprint in the industry.

-

The Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)