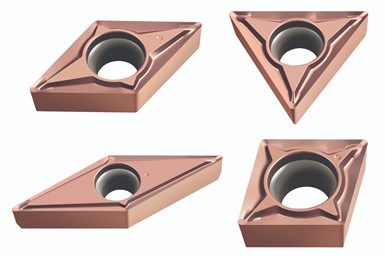

Walter Cermet Turning Inserts Boost Stability

Walter’s indexable cermet turning inserts use the company’s FP2 geometry to reduce vibration, produce stronger corners and enhance surface finish.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Indexable cermet turning inserts from Walter specialize in applications requiring a soft cut and high precision. The inserts achieve this balance of performance through FP2 geometry, which is a high positive (18-degree) rake angle geometry with soft hone that reduces cutting forces and vibration tendency. The inserts also extend tool life through WEP10C-coated cermet grade with multilayer TiCN TiAlN PVD coating and fine cermet micro grain. Walter says this combination of edge preparation and grade promotes dimensional stability over long periods of time, boosting productivity in mass production.

Walter’s FP2 geometry uses “minus tolerance” or “maximum corner radius” tolerance to present what the company says is a stronger corner radius than a standard ISO/ANSI corner radius. For example, machining a shoulder with a 0.0157" corner radius usually requires an ANSI-0.5 corner radius (0.0078"). With the FP2 geometry, however, machinists can use a 1M tolerance (equivalent of ANSI 0.0157" but 0.0146"+/-0.0008" tolerance corner radius). In addition to machining the same feature, the FP2’s corner radius also boosts tool life and surface finish. Walter recommends WEP10C cermet inserts for finishing thin-walled components, components with small diameters, long components and components with unstable clamping, as well as for fine boring applications.

Related Content

-

Tungaloy Expands Threading Tool Insert Offerings

The TungThread indexable threading tool series is designed for applications including general parts that are machined in CNC lathes and small precision parts in Swiss-type automatic lathes.

-

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

-

Sumitomo's Grooving Inserts Bypass Interference

Eastec 2023: The 90-degree inserts are said to be ideal for grooving narrow parts and facing in OD and ID applications that require unique approaches due to interference.

.png;maxWidth=300;quality=90)