Tungaloy Milling Inserts Enhance Cutting Performance

TungAluMill is designed for efficient machining of aluminum alloys and other non-ferrous materials at high speeds.

Share

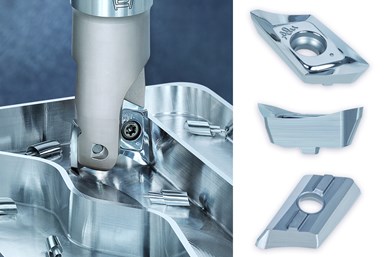

Tungaloy has introduced ten new XVCT-AM square shoulder milling inserts to expand its TungAluMill line designed for non-ferrous applications.

TungAluMill is intended for efficient machining of aluminum alloys and other non-ferrous materials at high speeds. The tool is designed to eliminate radial insert displacement caused by heavy cutting forces and strong centrifugal forces during high-speed rotation of the cutter, which is essential for efficient machining of aluminum parts. Additionally, the insert’s top and peripheral surfaces are ground and polished to a mirror-like finish, resulting in high-positive and sharp cutting edges that ensure soft cutting action, good surface finishing quality and prevention of built-up edge formation on the cutting edge.

Built on the features of the conventional XVCT-AJ inserts, the new XVCT-AM inserts introduce an enhanced interface design. This design improves insert retention during high-speed machining while reducing raw material usage for insert production, all without compromising cutting performance.

Related Content

-

Emuge-Franken End Mill Wins ANCA's Tool of the Year Award

Emuge-Franken received the award for its specialized tool based on the new Cera-Cut end mill design.

-

OSG End Mills Provide High-Efficiency Milling

The company has expanded its range of end mills with two offerings for high-speed milling.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

.png;maxWidth=300;quality=90)