Tungaloy Expands Grooving System With New Inserts

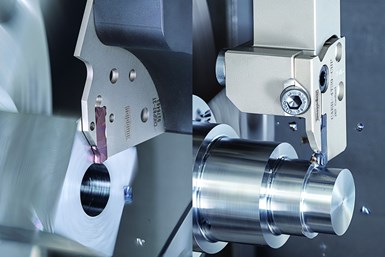

The company has added new insert options to its TungCut and AddInternalCut lines.

Share

Tungaloy announces an expansion of TungCut inserts with 87 total additional inserts in the latest physical vapor deposition (PVD) grades AH6235 and AH8005.

TungCut is a flexible grooving tool system offering a large variety of chipbreakers and toolholders that range from standard mono blocks to modular blades with through-coolant capabilities. According to Tungaloy, the insert clamping system provides the tool with process security and long tool life.

AH6235 is the latest titanium-enriched, nano-multilayered PVD coating with an extremely hard microstructure. Combined with a dedicated carbide substrate, the grade is said to provide the insert with exceptional reliability during parting and grooving operations with interruptions. AH8005 is another PVD grade incorporating high aluminum-content multilayered coating with high hardness. The grade integrates a dedicated carbide substrate with well-balanced hardness and fracture toughness, demonstrating superior wear resistance during high speed machining.

Together with the AH7025 grade, the AH6235 and AH8005 grades will enhance TungCut performances in parting and grooving operations with interruptions, as well as grooving and turning operations with aggressive conditions.

Tungaloy also expands its AddInternalCut indexable internal grooving tool system by increasing insert width options.

AddInternalCut internal grooving tool line features ground-to-precision inserts with four cutting edges. According to Tungaloy, the insert holding system provides tool rigidity and smooth chip evacuation, ensuring superior edge repeatability and precision machining.

The insert is clamped in the seat so that, in case the cutting edge is broken during machining, the remaining unused cutting edges are protected, enabling all four edges to be used. Being supported at three points when clamped in the seat, the insert provides accurate insert position repeatability and stable performance even in high speed and feedrate conditions. Furthermore, the insert is double sided and can be mounted on either a right- or left-hand toolholder, enabling easy inventory management.

AddInternalCut inserts are available in two sizes: The TCIG10 size is for internal grooving of minimum bore diameter of 10.5 mm (0.413") and up, and the TCIG12 size enables a maximum groove depth (CDX) of 3.0 mm (0.118").

The newly introduced AddInternalCut grooving inserts are capable of cutting extremely thin internal grooves of 0.5 mm (0.020"), as well as groove widths from 1.22-2.77 mm (from 0.048-0.109"), covering industry-standard groove profiles such as circlips and O rings.

Related Content

-

Custom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

-

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

.jpg;maxWidth=300;quality=90)