Tungaloy Adds Chipbreaker to Line of PVD-Coated Inserts

The PVD-coated insert grade series AH8000 performs in turning operations for heat resistant superalloys.

Share

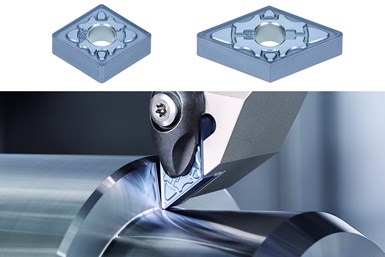

Tungaloy has expanded its AH8000 physical vapor deposition-coated (PVD) grade series of ISO turning inserts to include 14 new negative inserts with an SDM chipbreaker.

The PVD-coated insert grade series AH8000 performs in turning operations of heat resistant superalloys (HRSAs), which is made possible by nano-multi-layered AlTiN coating with high aluminum content and enhanced coating substrate adhesion. The series offers two grades: first-choice grade AH8015 is suitable from medium to finish cutting for a wide range of machining conditions, while AH8005 provides the insert with wear resistance that enables long and predictable tool life in high-speed continuous cutting operations.

The SDM chipbreaker features a T-land with variable widths and optimized rake angle that provide the insert with resistance against notch wear. Difficult metals like HRSAs are prone to cause notch wear on the insert cutting edge that can severely deteriorate insert tool life. Tungaloy says the combination of SDM geometry and the AH8000 grade series will extend tool life and provide superior predictability.

Complementing existing HRF chipbreaker for finish operations and HRM for finish to medium cutting operations, SDM further expands the application coverage of the AH8000 series, as well as contributes to machining cost reductions.

Related Content

-

Sandvik Coromant Inserts Provide Stable Turning of Aerospace Components

The new insert grades GC1205 and GC1210 cover a large application area within last-stage machining and intermediate-stage machining when turning aerospace engine components.

-

Tungaloy Expands Threading Tool Insert Offerings

The TungThread indexable threading tool series is designed for applications including general parts that are machined in CNC lathes and small precision parts in Swiss-type automatic lathes.

-

Sumitomo Turning Grade Improves Chipping Resistance

IMTS 2024: Sumitomo introduces its AC8115P custom steel turning grade, designed to improve chipping resistance.

.png;maxWidth=300;quality=90)