Touch Probe Stylus Helps Prevent Damage During Workpiece Collisions

Q-Mark Manufacturing highlights its TMC4-6053-C touch probe stylus.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

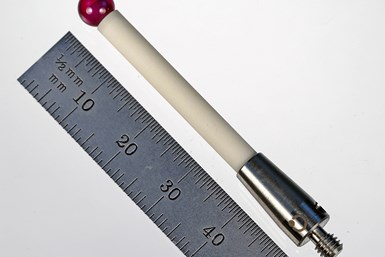

The TM4-6053-C from Q-Mark Manufacturing is the company’s most popular machine tool stylus. Weighing in at less than 5 grams, the stylus is 50 mm long from its stainless steel base to the center of its 6 mm diameter ruby ball and uses a 4.5 mm diameter ceramic stem.

Touch probes have the ability to multiply CNC productivity. On-machine touch probes can identify workpieces, align them to the machine tool axes and take mid-cycle measurements. In terms of unattended machine operation, Q-Mark says these tools have the potential to play an important role.

Many machine tool touch probes use styli with ruby balls and ceramic stems. Q-Mark also implements these features with its own styli as ceramic stems are lightweight, rigid and impervious to most coolants. A ceramic stem also serves as a mechanical fuse. During a rapid move, if the stylus unexpectedly collides with the workpiece, the ceramic stem breaks, helping prevent damage to the workpiece, the touch probe and to the machine tool itself.

Q-Mark says it makes ceramic styli for whatever touch probe a customer’s new or existing CNC machine is equipped with. The company’s factory manufactures its styli in southern California. Q-Mark reports the styli are always in stock and available for overnight delivery, and the company possesses the capability to quickly build custom ceramic styli to a customer’s exact specifications.

Related Content

-

ECI Machine Monitoring System Analyzes ERP Data in Real Time

IMTS 2024: ECI Software Solutions features its Alora machine monitoring system for real-time analyzation of ERP data and connection between staff and the shop floor.

-

6 Trends in Additive Manufacturing Technology

IMTS 2024 features a larger Additive Manufacturing Pavilion than ever before, with veteran suppliers alongside startups and newcomers at the front of the West Building. As you browse these exhibitors, as well as booths found elsewhere at the show, keep an eye out for these trends in AM.

-

FANUC Details Robotic Vision, ROBODRILLS and More at IMTS 2024

FANUC’s IMTS 2024 booth includes real-time demonstrations that show the abilities of its equipment, including robots, controllers and machine tools.