TDM Systems' Global Line 2019 Software Combines Workflow, Tracking Capabilities

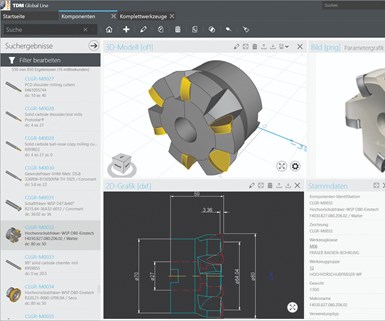

With the new release of TDM Global Line 2019, TDM Systems offers many of the functions of its core solution.

Share

With the new release of TDM Global Line 2019, TDM Systems offers many of the functions of its core solution, which includes TDM Shopfloor Manager, TDM Production Document Management, graphic functions and TDM WebCatalog.

“The global use of a central database results in massive IT cost savings, productivity increases and synergies that span multiple locations,” explains Eugen Bollinger, vice president of sales. “In order to increase the added value for the user even further, we have expanded the configuration options in TDM Global Line 2019 and developed new modules.”

TDM Shopfloor Manager is a tool designed to enable comprehensive workflow management, incorporating booking functions and interfaces for crib systems, presetting devices and machines as well as for higher-level systems such as MES, FMS and ERP. Users can now create multiple shopfloor configurations in order to depict workflows in various production areas. Individual status management enables a user to define the tool status themselves within the workflow.

TDM Production Document Management enables users to assign as many documents as they wish to the production resources via a drag-and-drop function, either in the form of a link to the actual saved location or as a copy on the TDM Global Line server.

With the release of TDM Global Line 2019, upon registering with TDM systems, users will have access through the TDM WebCatalog to the latest tool catalogs in the cloud. This means users can obtain consistently up to date, verified tool data from leading manufacturers.

Related Content

-

Leveraging Data to Drive Manufacturing Innovation

Global manufacturer Fictiv is rapidly expanding its use of data and artificial intelligence to help manufacturers wade through process variables and production strategies. With the release of a new AI platform for material selection, Fictive CEO Dave Evans talks about how the company is leveraging data to unlock creative problem solving for manufacturers.

-

Diving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.