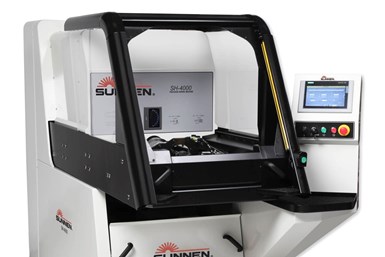

Sunnen's New Servo-Precise Machining Center

Eastec 2021: Sunnen’s new honing machine is engineered for medium to high production of parts with bore diameters from 1.5 to 102 mm (0.060" to 6.50").

Share

Sunnen’s new horizontal SH-4000 – which the company will showcase in booth 2113 at Eastec – introduces servo-precise, digitally repeatable performance, touchscreen HMI, infinite part program storage, larger workpiece capacity and operator safety features.

The SH-4000 is engineered for medium to high production of parts with bore diameters from 1.5 to 102 mm (0.060" to 6.50"). Sunnen says it is capable of processing a wide variety of part sizes and configurations. It features a 4.1 kW (5 hp) spindle drive and 1.1 kW (1.5 hp) stroker drive with 400 mm (15.75") stroke length. Spindle speed is adjustable from 200 to 3,000 rpm, with stroke rates of 10 to 550 spm.

The SH-4000 introduces digital-servo tool feed and cutting pressure control throughout the pressure range. Cutting pressure can be adjusted in 4.5 N (1 lbf) increments to a new maximum of 2,224 N (500 lbf). Sunnen says the digital system provides superior feed control at low pressures for improved honing results with small-diameter parts. Two-step honing allows high stock removal, coupled with a precise finish step, all in one operation. In addition, the new tool feed system includes 20 mm (0.79") additional travel for increased diameter range when using high-production tooling.

The SH-4000’s servo ballscrew stroker delivers precision and repeatability for honing in blind bores, while a longer stroke length of 400 mm (15.75") allows the new machine to take on deeper bores. The machine's stroking system can be controlled with a joystick on the operator station. In addition, the Siemens 225 mm (9”) touchscreen control features infinite part program storage and intuitive setup and run screens.

The standard coolant system is nearly 70 percent larger than earlier machine models at 208 L (55 gal), and is apparently designed for easy maintenance. It is equipped with quick-disconnect lines and level gauge, and removes from the front on casters.

Related Content

-

How to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

-

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

-

High RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

.jpg;maxWidth=300;quality=90)