SolidCAM Software Solutions Streamline CNC Machining

Westec 2023: SolidCAM’s iMachining provides users with optimal automatic feeds and speeds with the patented Technology Wizard.

Share

ECi Software Solutions, Inc.

Featured Content

View More

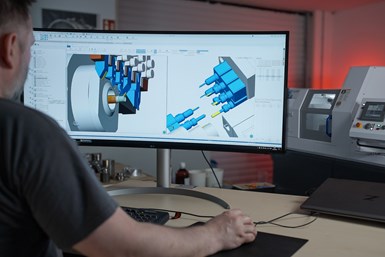

SolidCAM highlights CAM solutions for faster, more efficient machining — seamlessly integrated and associative in Solidworks, Solid Edge and Autodesk Inventor — in booth 1631 at Westec 2023.

SolidCAM’s iMachining is said to save 70% or more in CNC machining time, increase tool life 5X or more and provide users with optimal automatic feeds and speeds with the patented Technology Wizard.

Additionally, SolidCAM’s Multi-Channel mill-turn and Swiss-type CAM includes post-processors for all complex mill-turn and Swiss-type CNCs. Users can optimize their machining with SolidCAM’s Multi-Channel synchronization and see complete machine simulation for safer machining.

Users can leverage metal 3D printing with SolidCAM Additive, which provides cost-effective, combined 3D metal printing and CNC machining. With hybrid manufacturing, users can 3D print a part in metal, then CNC finish it, saving costs compared to traditional manufacturing. SolidCAM helps guide the entire process from design to 3D printing to CNC machining.

Related Content

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)