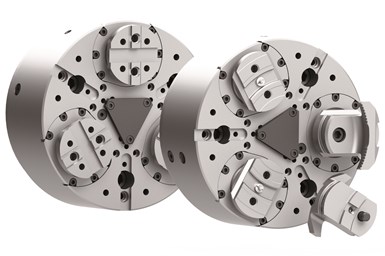

SMW TX Series Chucks Operate Six Months Without Lubrication

SMW Autoblock TX Series three-jaw pull-down chucks features a symmetrical master-jaw design that promotes a long lifetime and consistent part quality.

Share

Autodesk, Inc.

Featured Content

View More

SMW Autoblok says its TX Series three-jaw pull-down chucks feature repeatability of up to 4 µm (0.00015”) and precise, self-centering accuracy for heavy-duty metal-cutting applications.

The TX Series features the TX-C (tongue and groove) and TX-RV (quick jaw change) models. SMW Autoblok recommends both versions for first and second operations, saying they provide exceptional parallelism for each.

A unique symmetrical master-jaw design disperses cutting forces over a wide area, allowing the chucks to hold their accuracy for a long lifetime and ensuring constant workpiece quality. The master jaw design also allows for inner diameter (ID) and outer diameter (OD) gripping with optimal stability and without the changes that regular ball-lock chucks require. Integrated centrifugal force compensation provides constant clamp force at higher speeds and feeds, reducing production time.

The TX Series is Proofline-sealed to reduce maintenance, and the company says these workholders will run 24/7 for six months without adding additional lubrication. The TX-RV model features a unique quick-change top jaw for part families, and both TX models have active pull-down for enhanced plane parallelism. The chucks are available in size ranges of 170, 210, 250, 315, 400 and 530 mm.

Related Content

-

Custom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.

-

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

-

Prioritizing Workholding Density Versus Simplicity

Determining whether to use high-density fixtures or to simplify workholding requires a deeper look into the details of your parts and processes.