SMW Autoblok's MM e-motion Leverages Industry 4.0 Tech

SMW Autoblok’s MM e-motion power chuck can save, recall and share grip force and positioning data across machines through Industry 4.0 technology.

Share

Autodesk, Inc.

Featured Content

View More

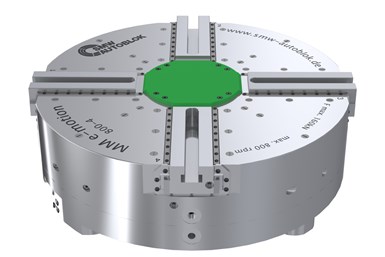

The fully sealed MM e-motion four-jaw chuck from SMW Autoblok provides contact-free adjustment of gripping forces without unclamping parts during every phase of the production process.

Individual electro-mechanical drives independently control and monitor each jaw of the MM e-motion, allowing for clamping functions like self-centering, compensating, and individual jaw movement within one fully automated chuck.

SMW Autoblok recommends the MM e-motion for mill-turn applications and horizontal and vertical lathes, especially when conducting heavy-duty precision machining of easily deformed workpieces. The power chuck conducts automatic center adjustments for any workpiece shape or configuration, including round, square, rectangular and irregular shapes as well as workpieces with different wall thicknesses. The MM e-motion is also available in a lightweight version optimized for situations with limited mill-turn load bearing capacity on the spindle. This version features the same functionality as the standard MM e-motion yet allows for higher workpiece weight and more usable Z stroke.

The chuck body and internal parts are case-hardened for increased chuck life, rigidity, precision and durability. The chuck accepts inch-serrated top jaws and is available in sizes from 500-1250 mm.

Users can store and recall grip force and jaw positions when repeating processes, using Industry 4.0 technology to interchange digital data between machines in the same production facility or worldwide.

SMW Autoblok’s MM e-motion uses the newly developed F280 wireless inductive radial coupler system that transmits energy and data contact-free through an air gap of approximately 3 mm between rotating and stationary components. The IP67-rated inductive coupler system includes a stationary coupler and a movable mobile coupler. The stationary coupler is incorporated into the machine or set-up station and the mobile coupler is incorporated on the pallet side. The couplers support power transfer up to 1500 watts and data transfer of two CAN bus channels and two digital signals.

Related Content

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

-

Shop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

-

Fixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)