MC Machinery's Sinker EDMs Feature AI Adaptive Control

The artificial intelligence adaptive control technology is said to help optimize performance, improve productivity, reduce electrical consumption and take the guesswork out of estimating machining time.

Share

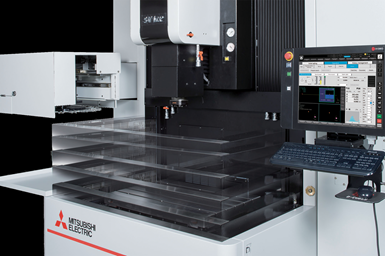

Photo Credit: MC Machinery

MC Machinery’s latest EDM and precision milling technology includes wire and sinker EDMs, machining centers and automation. The company, a subsidiary of the Mitsubishi Corporation, is a supplier and servicer of fabrication and milling equipment, including Mitsubishi lasers, EDMs and automation systems.

The new Sinker EDMs feature artificial intelligence (AI) adaptive control technology. The company says the Mitsubishi SV12P and SG12 sinker EDMs optimize performance, improve productivity, reduce electrical consumption and take the guesswork out of estimating machining time.

The AI technology is said to make logical use of condition-monitoring data. For example, these new machines can diagnose real-time problems within the burn and directly modify specific parameters for a stable and accurate output. This enables machine operators of all experience levels to produce quality results in complex cavities and shapes.

Because the AI technology analyzes current sensor data to determine optimal conditions, it reduces overall electrode wear and costs. According to the company, by monitoring these parameters, the machine operates more efficiently and can more accurately predict machining times.

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.