Siemens CAM Software Update Provides Streamlined Workflows

NX for manufacturing features new product updates to NX CAM, NX CAM On-Machine Probing and more.

Share

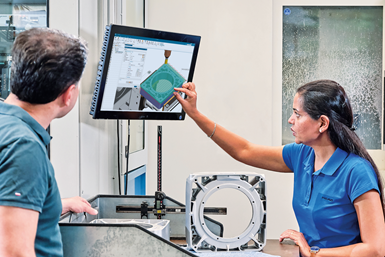

Siemens Digital Industries Software has announced the latest version of NX for manufacturing, which includes new features and product updates to NX CAM, NX CAM On-Machine Probing and more.

The new quick roughing operation in NX CAM software offers a swift and easy-to-program offset roughing process with a user-friendly interface and streamlines the creation of roughing operations with minimal input. The new face milling operation provides modern programming techniques to interactively adjust toolpath parameters. The operation now features zig-zag patterns to make it easier for users to program face milling toolpaths. Additionally, the latest wall finish barrel swarf operation helps users reduce machining time and improve surface finish using advanced settings to generate optimized toolpaths easily. Users can now use taper barrels for parts with straight walls and tangent barrels for parts with curved walls.

With the upgraded Cloud Connect Tool Manager, users can easily generate entire tool assemblies using the dynamic assembly tool preview. The inclusion of toolholders in the latest release enables seamlessly create tool assemblies with tool holders and cutting tools. The module supports several search functions for added convenience, and existing assembly tools saved in the previous version of the library can be quickly and automatically converted.

The latest mill-turn workpiece feature offers more intuitive, faster creation of advanced mill-turn CAM setups. This enhancement, available for use only when a machine tool is loaded, can reduce the need for additional setup efforts by combining the definitions of milling and turning workpieces into a single geometry object.

The NX CAM On-Machine Probing module provides comprehensive measurement technology to optimize the manufacturing process and improve workpiece quality. The latest enhancement provides an intuitive user interface, where all parameter possibilities and available cycles are visualized with a tooltip and an image. NX On-Machine Probing post-processor and simulation add-ons are available for free via Siemens NX CAM Post Hub. The latest improvements include the addition of layers for postprocessor and simulation extensions for commissioning.

Related Content

-

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

-

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

.jpg;maxWidth=300;quality=90)