Siemens Adds New Motors for Sinamics S210

Siemens has introduced new servo motors for its S210 single-cable servo drive system: Simotics S-1FS2, S-1FK2 and S-1FT2.

Share

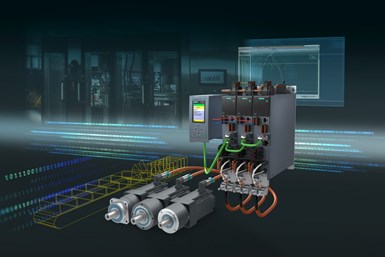

The new Simotics S-1FK2 servo planetary gearmotors complement the Sinamics S210 servo drive system.

Photo Credit: Siemens

Siemens is adding new servo motors to its Sinamics S210 single-cable servo drive system, with the aim of expanding its range of applications: the S-1FS2, for pharmaceutical and food industries; the S-1FK2, for applications that require high cycle rates and low-inertia design or inertia matching; and the S-1FT2, for additional options.

The Simotics S-1FS2 motor has a stainless-steel housing, IP67/IP69 ratings and high-resolution 22-bit absolute multiturn encoders. The company says that it meets all hygienic conditions and can be used for mixing and stirring, air conditioning and ventilating, dosing and filling, as well as conveying, packaging and storing end products in the food and beverage sector or in the pharmaceutical industry.

The Simotics S-1FK2 servo planetary gearmotor is designed for high cycle rates that require a lightweight, low-inertia gear design, or when inertia matching is required to precisely move heavy items. The motors are ready-mounted and the units are available in a range of gear ratios and sizes. Thermal dimensioning is done via the digital twin in the TIA (Totally Integrated Automation) Selection Tool.

The Simotics S-1FT2 is a servo motor that offers a range of options for the Sinamics S210 system. For example, encoders with a resolution of up to 26 bits improve system accuracy, and the IP67 protection rating and various motor coatings make the solution suitable for use in harsher environments. In addition, new machine options, such as higher rated speeds, are available for extended use.

The Sinamics S210 servo drive system consists of a servo converter and servo motor. All motors of the servo system are connected via a single cable that combines power wires, encoder signal and brake in one line. The range of applications includes dynamic servo solutions, such as those found in handling systems, packaging machines and machine building applications. The system works with the Simatic S7-1500 controller via Profinet IRT for applications the require a high degree of motion control, such as dynamic positioning, gear synchronization or cams with multiple axes.

.JPG;width=70;height=70;mode=crop)