Schunk's New Chuck Jaw Clamps a Range of Geometries

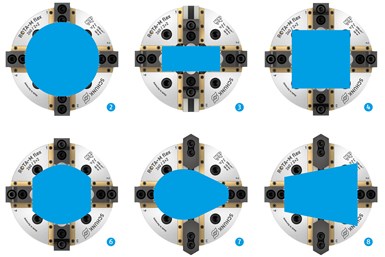

Schunk’s Rota-M Flex 2+2 chuck jaw is designed to provide increased flexibility for clampable workpiece geometries and a variety of possible applications.

Share

Schunk’s new Rota-M Flex 2+2 chuck jaw is designed to provide a longer compensation stroke than other available four-jaw chucks on the market. Depending on the size, it amounts to 5.1 mm up to 10 mm per jaw. According to Schunk, the result is increased flexibility for clampable workpiece geometries and a variety of possible applications. In many cases, a single Rota-M Flex 2+2 chuck is capable of covering a wide range of part geometries.

The patent-pending compensating mechanism of the Schunk Rota-M Flex reportedly provides a significantly larger compensation stroke than comparable lathe chucks, which results in increased flexibility in view of clampable workpiece geometries. Photo Credit: Schunk

Grease rinse out and gradual loss of clamping force is prevented with special seals on the guideways. Schunk claims that even in instances of low clamping forces, precise functioning of the chuck is ensured. The sealings also protect the chuck body against chips and dirt, increasing process safety and extending maintenance intervals.

The Schunk Rota-M Flex 2+2 clamps in a self-locking manner, and the clamping condition is signaled via indicating pins. The standard chuck sizes 260 to 1200 achieve jaw strokes from 9.5 mm to 17.8 mm and high clamping forces from 100 kN to 180 kN.

The chuck face is equipped with grooves, and fixed stops enable the chuck to also be used as a vise. In addition, the large sizes are designed for use on vertical lathes. The Schunk Rota-M Flex 2+2 comes equipped with a flexible serration (1.5 mm × 60° or 1/16" × 90°).

Related Content

-

Workholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

-

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.