Roto Tech Expands Line of Rotary Grinding Tables

Roto Tech Inc. a set of angular contact bearings for low friction while holding tight tolerances and triple seals for aggressive environments.

Share

Autodesk, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

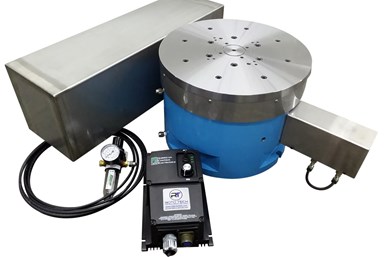

Roto Tech Inc. manufactures precision rotary grinding/lapping tables that are used with surface grinders, jig grinding machines, vertical machining centers and other machines to accomplish grinding/lapper operations not possible with the machine tool itself. The company has expanded its product offering in the silicon, quartz and ceramic industries with the Roto Grind model 1012HD rotary table. It features a robust steel housing, a set of angular contact bearings for low friction while holding tight tolerances, triple seals for aggressive environments, porting through the spindle for vacuum chucks and optional pneumatic table locking system. The portable control unit converts AC line voltage to DC power for the 1 hp motor providing variable speed range of 10-175 rpms in either clockwise or counter clockwise rotation.

Roto Tech Inc. offers a complete line of precision rotary grinding/ lapping tables from 7" to 24" diameter in either standard, low profile or heavy-duty configuration. Optional features include air bearings, air purge, special rpm speed ranges, heavy duty motors, manual shot pin table index, magnetic chucks and sine plates for angular configuration for grinding cutters and chamfers/radii on components. These rotary grinding/lapping tables can be custom built and used for inspection and assembly.

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)