Paperless Parts Software Streamlines Quoting Process

The software streamlines repetitive, error-prone tasks associated with request for quote intake and prep work, allowing estimators to focus on high-value activities.

Share

Hwacheon Machinery America, Inc.

Featured Content

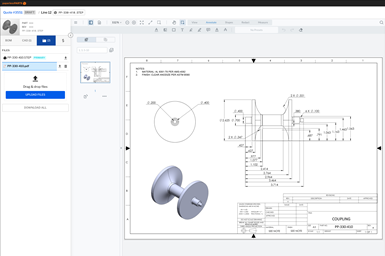

View MorePaperless Parts has announced the launch of its new AI-supported quote setup workflow, which streamlines the repetitive, error-prone tasks associated with request for quote (RFQ) intake and prep work, allowing estimators to focus on high-value activities.

The new quote setup workflow tools, available at no additional cost for all Paperless Parts customers, include:

- Email forwarding: Users can now forward an RFQ from their email inbox to Paperless Parts to instantly start a quote with all quote files attached.

- AI-powered line item extraction and file assignment: Paperless Parts uses AI to review RFQ emails and associated files for part information, build line items and auto-assign files to line items.

- RFQ file management: Quotes within Paperless Parts now have a designated area for storing and organizing all files related to a quote — emails, part files, vendor quotes and more — for easy organization and assignment to line items.

- Bulk and drag-and-drop line item creation: With this new release, creating and manipulating line items has never been faster. Users can copy and paste directly from an email or CSV, or manually manipulate line items, assemblies and supporting files with drag-and-drop functionality to organize quotes in a way that best suits their shop.

- PDF viewer with part setup tool: The platform’s PDF viewer makes it easier to pull data off of prints and into a quote by offering data entry fields side by side with prints, putting everything important on one screen. It also leverages AI to detect and suggest data fields for critical part information.

- Malware and virus scanning: Paperless Parts automatically scans files for malware and viruses upon both receipt and download.

Jason Ray, co-founder and CEO of Paperless Parts, says, “Today, some of the most experienced people inside a shop are wasting hundreds of hours per year performing repetitive administrative tasks just to get to the point where they can determine which quotes to prioritize. That is a process that, with the right tools, can largely be automated.” Ray continues, “Paperless Parts customers can do more with fewer resources and get quotes out faster.”

Paperless Parts CTO Jason Luce adds, “Our goal with launching the new quote setup workflow is to get estimators working on high-value activities as quickly and efficiently as possible.”

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

ERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.