ModuleWorks Update Optimizes Multiple Processes

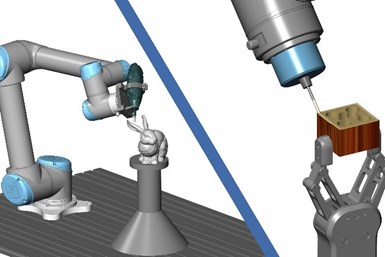

ModuleWorks’ 2020.08 CAD/CAM software update includes a variety of new and enhanced features across all of ModuleWorks’ machining software lineup.

Share

ModuleWorks’ 2020.08 CAD/CAM software update is available for download from the company’s website. This marks ModuleWorks’ second major software update of the year, encompassing new and enhanced features across its entire product line. Features include updates to rotary machining, additive manufacturing, three-axis machining, simulation and Mult-Axis Post Processor (MultiXPost).

Users can now perform roughing cycles with an axis offset for rotary machining. This process uses the cutting edges instead of the tool center to achieve more stable cutting speeds and close-to-diameter cutting with non-spherical tools. The offset is always against the direction of rotation, changing position when the rotation direction changes. This movement is linear to prevent tool damage and ensure a safe cutting process.

ModuleWorks’ 3+2-axis additive manufacturing uses five-axis printing machines to print extreme overhang areas without needing support structures. This accelerates the manufacturing process and delivers a higher quality finish with reduced staircase effects.

Three-axis machining users can have full control over their toolpaths, and can now access advanced options like cutter compensation and tangential arcs. Users can also add additional cuts along part boundaries to remove uncut cusps and improve final product quality.

The new interactive smart-measure touch screen tool is designed to quickly and accurately measure stock and arbitrary meshes. Automatic feature identification and intelligent snapping help users set precise measurement points, while drag and drop functionality helps measure distances between the stock and the machine as well as depths, clearances, angles and radii.

MultiXPost now supports posting on n-axis machines. This opens new possibilities for generating G-code for n-axis machines and simulating robotic applications. The software also offers new parameters and returns machine axis values to give users full control over machine movements. MultiXPost can use these machine axis values to drive simulations or generate NC G-code files.

Related Content

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

Bringing Machining In-House to Keep up With Demand for Offroading Parts

To meet demand increases for its Ford offroad industry components, supplier RPG Offroad brought its machining processes in-house, saving the company nearly $50,000 per month. Here’s how its choice of integrated CAD/CAM software made it happen.

-

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

.jpg;maxWidth=300;quality=90)