ModuleWorks Update Includes Enhanced Customization

ModuleWorks’ 2022.08 CAD/CAM software includes new custom tool shapes for roughing, automatic tool axis control and vector interpolation for the machine simulation.

Share

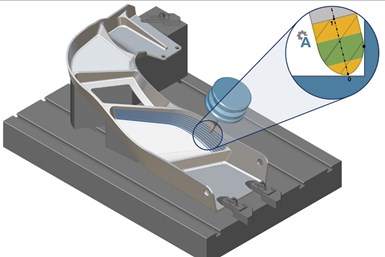

ModuleWorks, a leading software component provider for the digital manufacturing industry, announces the release of its 2022.08 CAD/CAM software components for digital manufacturing. This is the second major ModuleWorks release of 2022 and contains new and enhanced features across the entire product range, including new custom tool shapes for roughing, automatic tool axis control and vector interpolation for the machine simulation.

With a new feature for creating generic revolved tools, operators can customize the shape of the cutting and non-cutting parts of the tool for all triangle, mesh-based roughing strategies. Customized tools avoid over-simplifications because they take specific features of the tool shape into account during the toolpath calculation to deliver a realistic simulation of the material removal process.

This new feature for multi-axis finishing adds a new “Automatic” mode to the tool axis control. In automatic mode, the contact point as well as the lead and lag angles are automatically defined according to each available tool. This reduces programming time and simplifies tool-axis definition.

Additionally, the RTCP ON command in the ModuleWorks Machine Simulation has a new option called “by vectors.” Between any two moves, the Machine Simulation interpolates the tool’s movement to ensure the tool tip points are located on a line and the tool vectors are located on a plane. The size of the interpolation steps can be controlled, and the command requires no machine kinematic knowledge, making it straightforward to use.

Further details about the ModuleWorks 2022.08 release are available in the latest ModuleWorks YouTube videos: What’s New in ModuleWorks 2022.08.

The ModuleWorks 2022.08 release is available now for download from the ModuleWorks website.

Related Content

-

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

-

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

-

Continuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

.jpg;maxWidth=300;quality=90)