Meltio Offers Toolpath Generator Software for Metal 3D Printing

Meltio Horizon uses the laser-wire metal deposition process with the Meltio M450.

Share

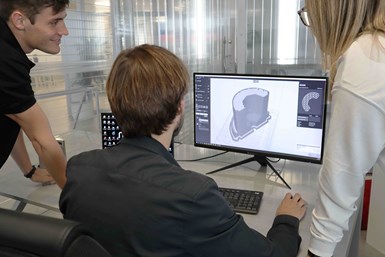

Meltio offers its proprietary toolpath generator software, Meltio Horizon, which provides a user experience tailored around its plug-and-play metal 3D printer, the Meltio M450. The new software uses the laser-wire metal deposition process with the Meltio M450. Meltio users had previously been reliant on third-party fused filament fabrication (FFF) slicers to prepare toolpaths for the Meltio M450.

In addition to traditional slicing parameters used in FFF software such as layer height, line width, print speed and support materials, the new Meltio Horizon provides access to Meltio’s laser-wire process, as well as material-specific parameters such as laser power, dual wire and hot wire settings.

With the Meltio Horizon software, all of the material-related settings are directly in the slicing software, enabling for full control and a single profile. This also enables users to create more specialized printing profiles, with the power to directly control the laser and hot wire on a per-slicing-feature basis, rather than being set for the full part.

This slicer is currently only compatible with the Meltio M450 metal 3D printer. For Meltio engines (CNC and robot integration), the company is currently working on developing its open software ecosystem partnerships that allow the generation of five-axis G codes.

Features of the Meltio Horizon include cost calculation per part in each project; custom build plates and work spaces; 2D and 3D previews; and convenient storing and sharing of the complete project file, consisting of the model file, workspace, build plate as well as gas and material profiles.

Updates of the Meltio Horizon and new printing parameters are available directly through the slicer. According to Meltio, new materials and printing profiles will be released periodically.

Related Content

-

Automated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

-

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.