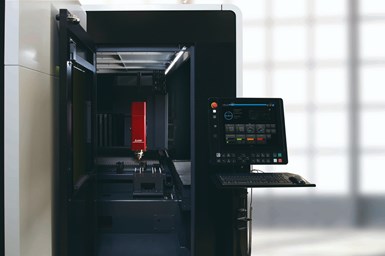

MC Machinery GX-F Advanced Fiber Laser System Simplifies Use

MC Machinery’s GX-F Advanced Series of fiber laser systems uses artificial intelligence to enhance operational simplicity and self-correct bad cuts.

Share

MC Machinery has released its GX-F Advanced Series of artificial intelligence-enabled fiber lasers.

AI technology reduces how much operator input is necessary to run the GX-F Advanced Series, making it easy-to-use for operators of all skill levels — especially valuable in the ongoing shortage of skilled manufacturing workers.

By integrating gas reduction technology, the GX-F Advanced Series also delivers more power while using up to 77% less nitrogen.

The Mitsubishi zoom head automatically changes the beam size, shape and focal point for each material, reducing setup time while also enabling the laser to process plates with a wide range of thicknesses. Up to a 60% reduction in piercing time makes it possible for the GX-F Advanced to pierce 25-mm-thick mild steel within 0.8 seconds.

Mitsubishi’s proprietary AI technology monitors the cutting process in real-time with audio and light sensors, automatically adjusting parameters to optimize cutting performance. If the AI detects a bad cut, the machine will make the required adjustments to improve or regain the cut. MC Machinery says the technology can also optimize cutting speed in all plates, no matter the plate quality. The AI nozzle monitor uses a camera system to monitor nozzle life, and the nozzle changer automatically replaces defective nozzles to support continuous processing.

Additional benefits of the GX-F Advanced Series include beam cleaning and anti-reflection technologies; on-site or remote monitoring of the cutting process; longer consumable life; augmented reality with drop and cut, part rotation and rectangular nesting; and real-time tracking of electric and assist gas consumption.

MC Machinery says the GX-F Advanced Series integrates with a wide variety of automation systems that increase productivity and reliability, including part sorting and material storage, loading and removal.

Related Content

-

How to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.