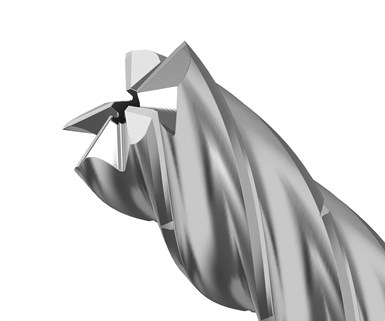

Kennametal's KOR 5 End Mill Enables Higher Feed Rates Roughing Aluminum

Kennametal’s KOR 5 solid carbide end mill is designed for high-speed aluminum roughing in aerospace applications.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Kennametal’s KOR 5 solid carbide end mill is designed for high-speed aluminum roughing in aerospace applications. The five-flute tool is said to allow for increased feed rates of 66% compared to three-flute tools.

A tapered core, variable-pitch design and 35-degree helix reduce chatter and tool deflection, the company says. Through-tool coolant flushes chips away while reducing heat. The tool’s chip splitter pattern is designed to break up long chips to avoid recutting while also contributing to surface quality.

The KOR 5 enables machining with low radial engagement but high depth of cut, resulting in higher metal removal rates than traditional methods, according to Kennametal. Use with the company’s Safe-Lock shanks increases the tool’s predictability and prevents pull-out at higher feed rates.

Related Content

-

OSG End Mills Provide High-Efficiency Milling

The company has expanded its range of end mills with two offerings for high-speed milling.

-

Kennametal's Expanded Tooling Portfolio Improves Performance

The company has launch eight new products that expand on and support existing platforms across multiple applications.

-

Tungaloy Expands Line of Barrel-Shaped End Mills

The new SolidMeister barrel end mills are efficient tools for complex 3D-surfacing operations used in mold making, orthopedic implants and the machining of other freeform surfaces.

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)