Jergens Pyramid Risers Provide New Angle for CNC Machining

Jergens’ pyramid risers feature a 30-degree mounting surface to ensure clearance for spindle and cutting tool paths, enabling more machining per setup.

Share

Autodesk, Inc.

Featured Content

View More

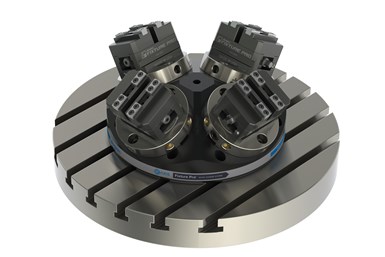

Jergens Inc.’s three- and four-sided pyramid risers permit multi-part load and provide greater access for five-axis machining applications. Part of the Fixture-Pro line of quick-change modular workholding solutions, the pyramid risers feature a 30-degree mounting surface to ensure clearance for spindle and cutting tool paths, enabling more machining per setup.

These solutions offer three mounting options. Direct-to-table uses t-slots, a center pin and a timing key, and is secured using t-nuts and socket head cap screws (SHCS). Quick Locating System (QLS) mounts are designed to accurately locate and clamp the pyramid to a base element, such as a subplate, using a combination of QLS shoulder screws and SHCS. Quick-Loc pallet systems use pull studs (spaced at the industry-standard 96-mm pattern) to locate and clamp in a single step.

The lightweight aluminum risers are compatible with virtually all five-axis CNC machining centers and ensure fast changeover and setup times. Available in both three-position and four-position configurations, the pyramid risers are designed to mate with many top tooling choices including self-centering vises, dovetail vises and ER collet fixtures.

Related Content

-

Using Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

-

Shop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

-

Navigating Large-Scale CNC Machining: Suburban Tool’s Niche Strategy to Stay Competitive

Facing increasing competition from lower-cost imports, Suburban Tool made a move toward large-scale, in-house machining. By identifying a niche in large, precision angle plates and tombstones, the company has strengthened its ability to control quality and protect its reputation.

.jpg;maxWidth=300;quality=90)