Jergens Improves Security on Line of Toggle Clamps

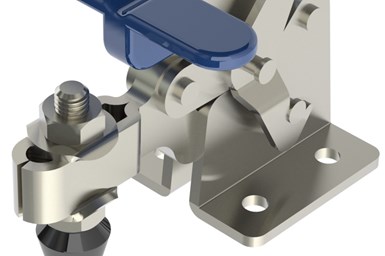

The new True-Lok clamps feature a locking mechanism that ensures they remain in the closed/hold down position for maximum security in workholding applications.

Share

Jergens Inc. expands its range of True-Lok toggle clamps with additional locking mechanisms, which the company says add security over a range of applications. Four types of clamps are available with the locking mechanism, including vertical handle, horizontal handle, pull (latch) style and push (straight line) style toggle clamps. In total, twenty-five new line items are offered.

According to Jergens, the locking mechanism ensures that the toggle clamp will remain in the closed/hold down position for maximum security in workholding applications. Additionally, it also ensures that the clamps remain in the unclamped/open position to facilitate part change and operator convenience.

True-Lok toggle clamps are available with flanged-base in either steel or stainless steel. Jergens says the secondary lever has been designed for thousands of cycles and easy access and engagement by the operator. Holding capacities range up to 7,700 lbs.

Related Content

-

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

-

Fixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

-

Custom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.