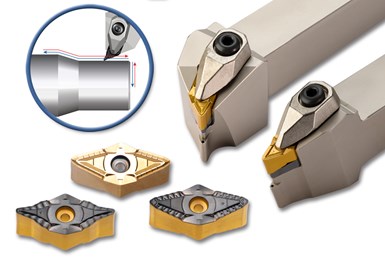

Ingersoll Introduces Superturnz Inserts

Superturnz, a multi-directional turning system that uses the front and back cutting edge of a four-corner insert, is now available from Ingersoll.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Ingersoll now offers Superturnz, a multi-directional turning system that uses the front and back cutting edge of a four-corner insert. According to the company, it is an alternative to conventional turning, where 80- and 35-degree corner inserts are fed in the same direction.

Superturnz uses all four directions available on a conventional two-axis lathe (+Z, -Z, +X and -X) to maximize material removal. The double-sided positive SuperTurnZ inserts have the same axial and radial rake angle and capability as standard ISO positive inserts, allowing for low cutting forces, but with additional cutting edges and higher feed rate capabilities, according to Ingersoll.

Related Content

-

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

-

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

.JPG;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)