In-Port Sequence Valves Enable Faster Deep-Hole Drilling

IMTS22: Vektek’s in-the-port sequence valves enable a single circuit to sequence up to a dozen individually sequenced devices.

Share

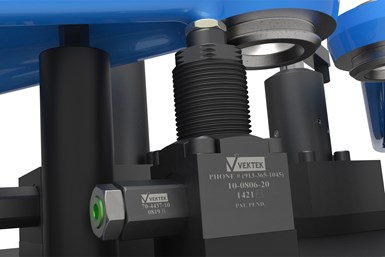

Vektek says it has revolutionized hydraulic circuit sequencing by eliminating the need for complex, multiple circuit deep-hole drilling with its in-the-port sequence valves.

According to the company, users can save time and money reducing their design time and deep hole drilling. Vektek will be at IMTS booth 431922 to demo how its in-the-port sequence valves enable a single circuit to sequence up to a dozen individually sequenced devices. These valves can be installed directly into the device port and can be individually adjusted to sequence or time users’ clamps.

Three pressure ranges are available, as well as adjustability within each range. These sequence valves work with flange-manifold mounted Vektek Port Ready devices and can be added after the design and build process.

Vektek says it provides latest in hydraulic clamping solutions across a wide range of applications. Its manufacturing facility is in Emporia, Kansas.

Related Content

-

Custom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

-

Kennametal's Expanded Tooling Portfolio Improves Performance

The company has launch eight new products that expand on and support existing platforms across multiple applications.

-

Tungaloy Drills, Milling Inserts Provide Enhanced Stability

Tungaloy has expanded its DrillForceMeister and TecMill lines with new drill bodies and milling inserts.

.png;maxWidth=300;quality=90)