HCL CAMWorks-Zoller Combination Streamlines Tool Management

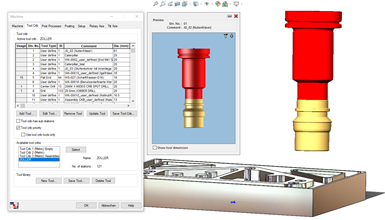

HCL CAMWorks has implemented Zoller’s Tool Management Solutions Interface, simplifying tool database management and minimizing manual tool data entry.

Share

HCL Technologies has implemented the Zoller TMS Tool Management Solutions Interface in its HCL CAMWorks software. This interface supplies CAMWorks users with tool database management options and an overview of available tools, eliminating the need to maintain multiple tool databases.

Using the Zoller interface in CAMWorks standardizes tool data and automates the exchange of data between the two software systems. Customers enter the information for their cutting tools into the central Zoller tool database, and the tools automatically import into CAMWorks. The software captures tool parameters such as the specific tool type, contour line for the holder and cutter and technology data (e.g. feeds and speeds). The interface also allows users to define tools in the Zoller software with the same tool types and parameters they are using in CAMWorks.

This software combination decreases the need for manual tool data entry and streamlines tool management. Once a part model is programmed, the Zoller Interface generates a setup sheet that includes a list of tools used for the part. This setup sheet assists with tool assembly, measurement and importing part cutting measurements to the machine.

Related Content

-

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

Continuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

.jpg;maxWidth=300;quality=90)